And how does digital shop floor management ensure greater transparency, better collaboration and more efficient processes?

Every production process is dynamic. And there are countless variables that determine how productive or effective production is. In the digital factory, these variables in the form of real-time information or real-time data are the constant basis for the ongoing progress of production. Data such as utilization rates, OEE, the most common reasons for errors, employee productivity or energy figures are essential for assessing the efficiency of your own production.

The access and availability of real-time information brings many advantages, as it replaces analog processes with digital systems, making them more efficient, transparent and responsive. For example, the status of current production can be compared with the specifications from order planning and ERP at any time. It also provides active support in identifying faults and deviations in the processes and taking action at an early stage. The MES Software EMC reliably records and bundles all real-time data on the shop floor and utilizes it as required – for example as real-time dashboards of current production, in the planning of machine occupancy, in analysis or in the creation and distribution of reports.

The most important benefits of digital shop floor management are

- Real-time transparency about the production status

- Faster problem solving and escalation management

- Reliable visualization of ongoing production

- Time savings, increased efficiency and productivity of employees

- Better data basis for decisions

Know what’s going on

Both the actual value of the current production and the target value of the order are displayed directly on the MES terminal at the machines at all times. The worker can see the current order progress at a glance and can intervene if necessary. Thanks to the rapid intervention, regular operation is restored promptly, resource utilization is increased and deadlines are met.

Increasing efficiency begins with recognizing the need for action

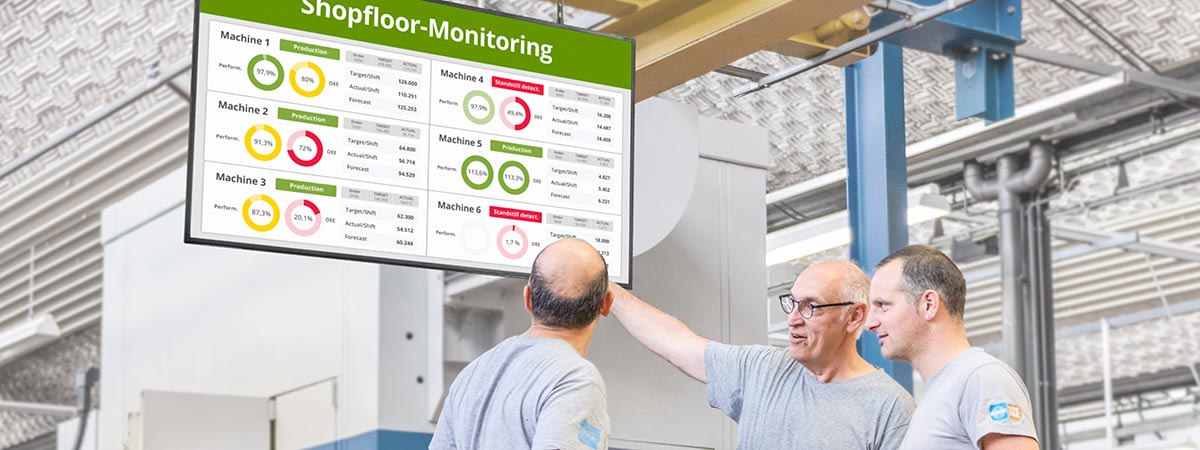

Every employee has a simple and intuitive overview of ongoing production at all times. With the help of individual dashboards both on the desktop and on large screens directly on the shop floor, meaningful real-time key performance indicators (KPIs) such as OEE (Overall Equipment Effectiveness), throughput times, reject rates etc. are visualized. This means that everyone always has an overview of the current order progress, key production figures or productivity. Directly in your dashboards and in real time. This means that machine downtimes, reduced speed, quality losses and system malfunctions can be identified immediately. Potential sources of error are visible at an early stage and countermeasures can be initiated promptly.

Productivity is driven by structured and systematic action

The visualization of real-time information directly on the shop floor supports employees in the structured and targeted implementation of measures. They have an overview of the progress of production at all times. In addition, it is easy to check whether decisions or measures taken are effective.

This transparent presentation of ongoing production via dashboards sustainably improves collaboration and communication between employees. All with the aim of achieving more more quickly together.

Sustainable optimization of processes through continuous improvement

Historical and current data is systematically recorded and evaluated. This enables realistic analyses and reports. Not only can orders or machines be compared, but risks and potentials can also be quickly identified through important analyses such as OEE of systems, setup levels, system downtimes, planned/actual time analyses of articles or productivity figures.

EMC Reporting enables an honest performance analysis and process optimization of production based on well-founded machine and production data. This enables systematic root cause analyses to be carried out.

With the help of well-founded corrective measures and effectiveness checks, improvements are integrated into the company processes on a sustainable and continuous basis.

Automated report distribution

A large number of reports can be generated from the real-time data and automatically distributed to the relevant employees or departments.

The systematic execution of analyses and evaluations with the system reports shows cause and effect in process management and controlling. Important insights can be gained from the analyzed data and better decisions can be made. This means that success can be measured at any time and in real time.

Conclusion

Real-time information is the gold of any production. It enables efficiency and productivity to be actively displayed and evaluated at any time. The real-time production data collected is used precisely where it is useful. This makes working methods easier in the long term.

Thanks to the significantly increased level of transparency regarding ongoing production, you always know where which order is running with which item and with what progress. Delays are immediately visible, problems with material, articles or tools are quickly detected and enable a prompt response.

The knowledge gained from the recorded real-time data is permanently anchored in the system and thus offers the opportunity to gain in-depth analyses of your own production. Important adjustments can thus be found and optimized quickly. With digital shop floor management, nothing stands in the way of a continuous and sustainable improvement process.

Contact us

Do you have further questions about how to use the recorded data from your shop floor with our MES Software EMC or about implementing your digital factory?

We will be happy to advise you and provide you with a personalized offer.

Simply call us on +49 7127 – 9231 10 or send us an e-mail to info@ite-ms.de

Frequently asked questions

How is real-time information recorded on the shop floor?

Real-time information is recorded and displayed directly on the machines by the MES Software EMC.

What are the advantages of using real-time data?

Real-time data enables quick identification of problems, better resource utilization and increased transparency in production.

What is a dashboard in the context of shop floor management?

A dashboard is a visual representation of real-time key figures such as OEE, throughput times and reject rates that are displayed on the shop floor.

How does reporting support decision-making?

Automated reports provide decision-makers with well-founded data that enables an objective evaluation of measures and processes.

What does escalation management mean on the digital shop floor?

Escalation management refers to the structured and timely response to deviations or disruptions in production, based on real-time data.