Meaningful analyses and reports

of production

Intelligent manufacturing analysis for easy control of the continuous improvement process and tracking of target achievement

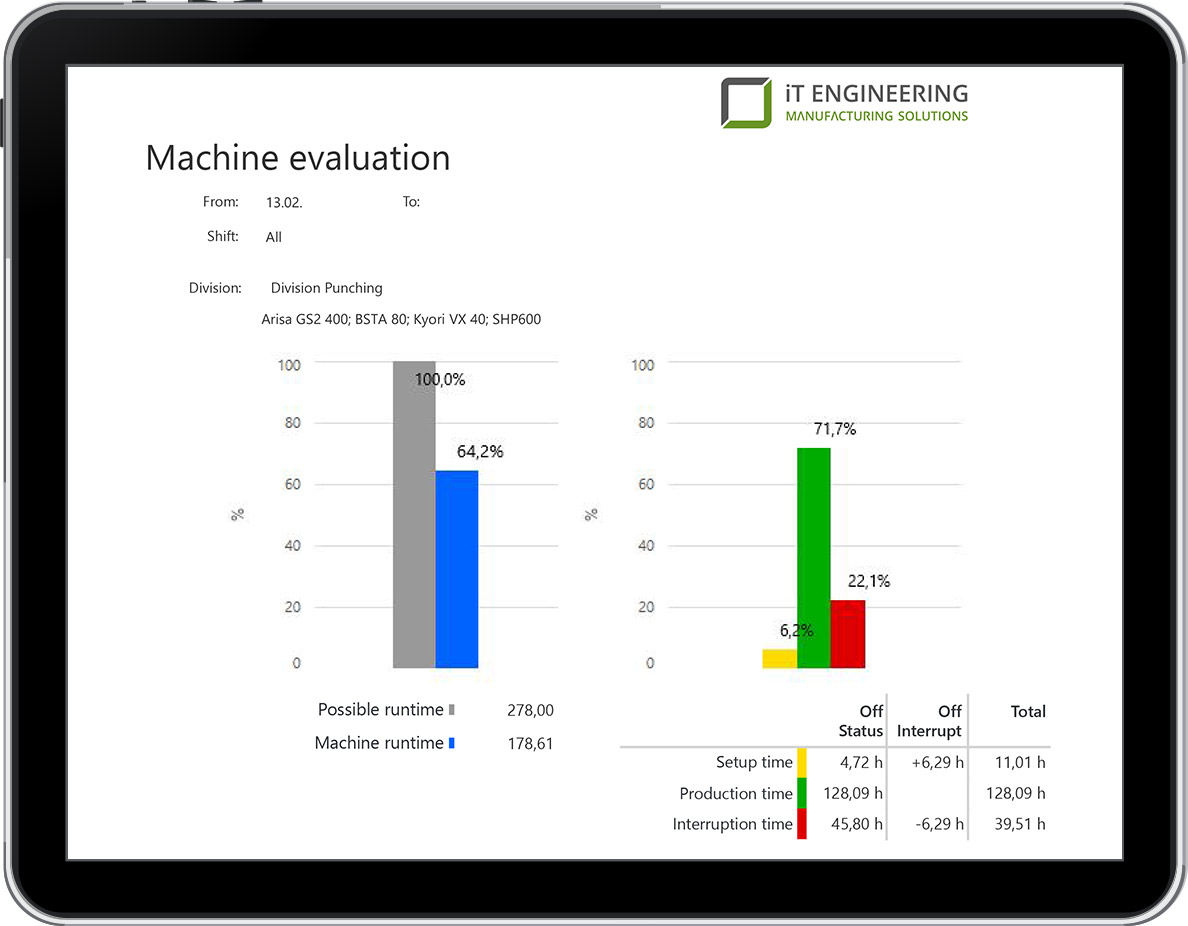

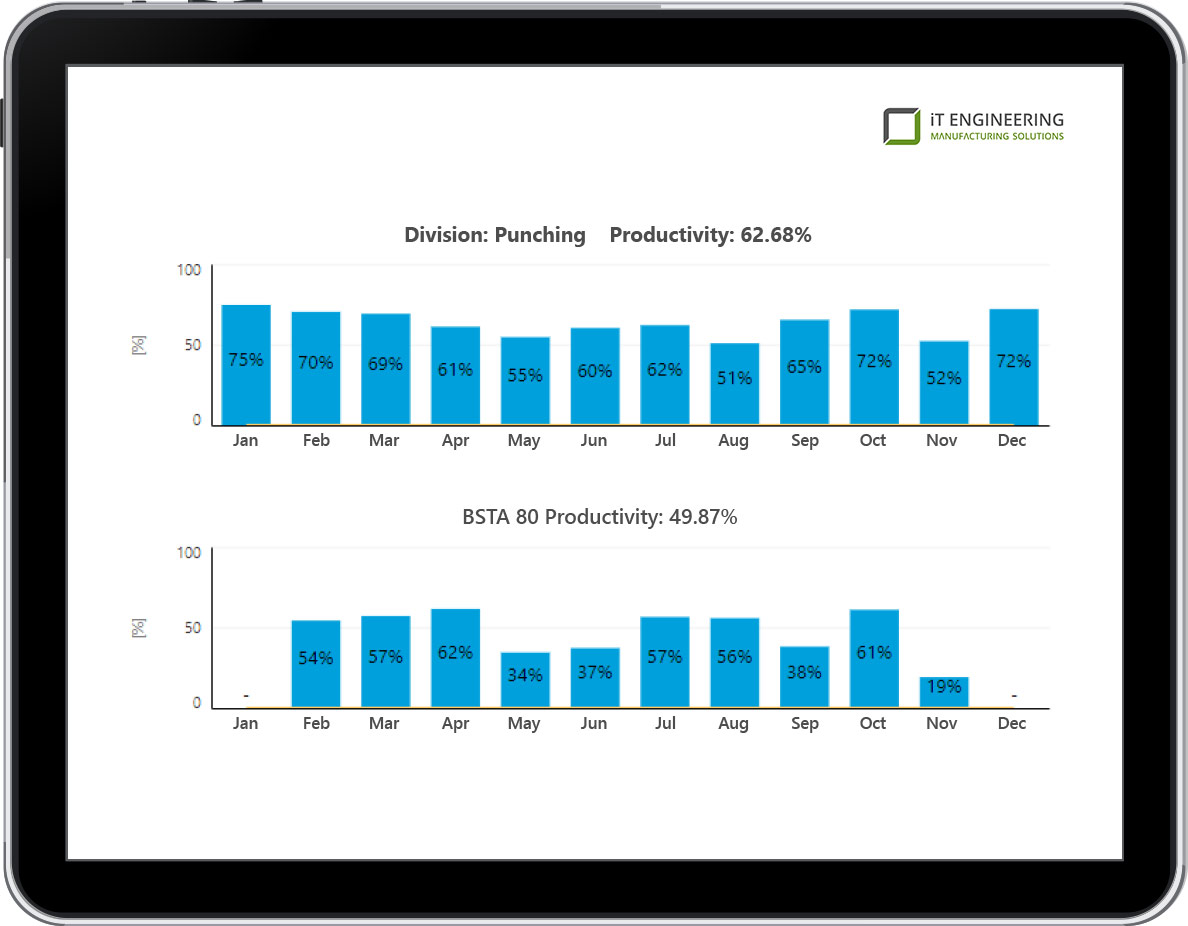

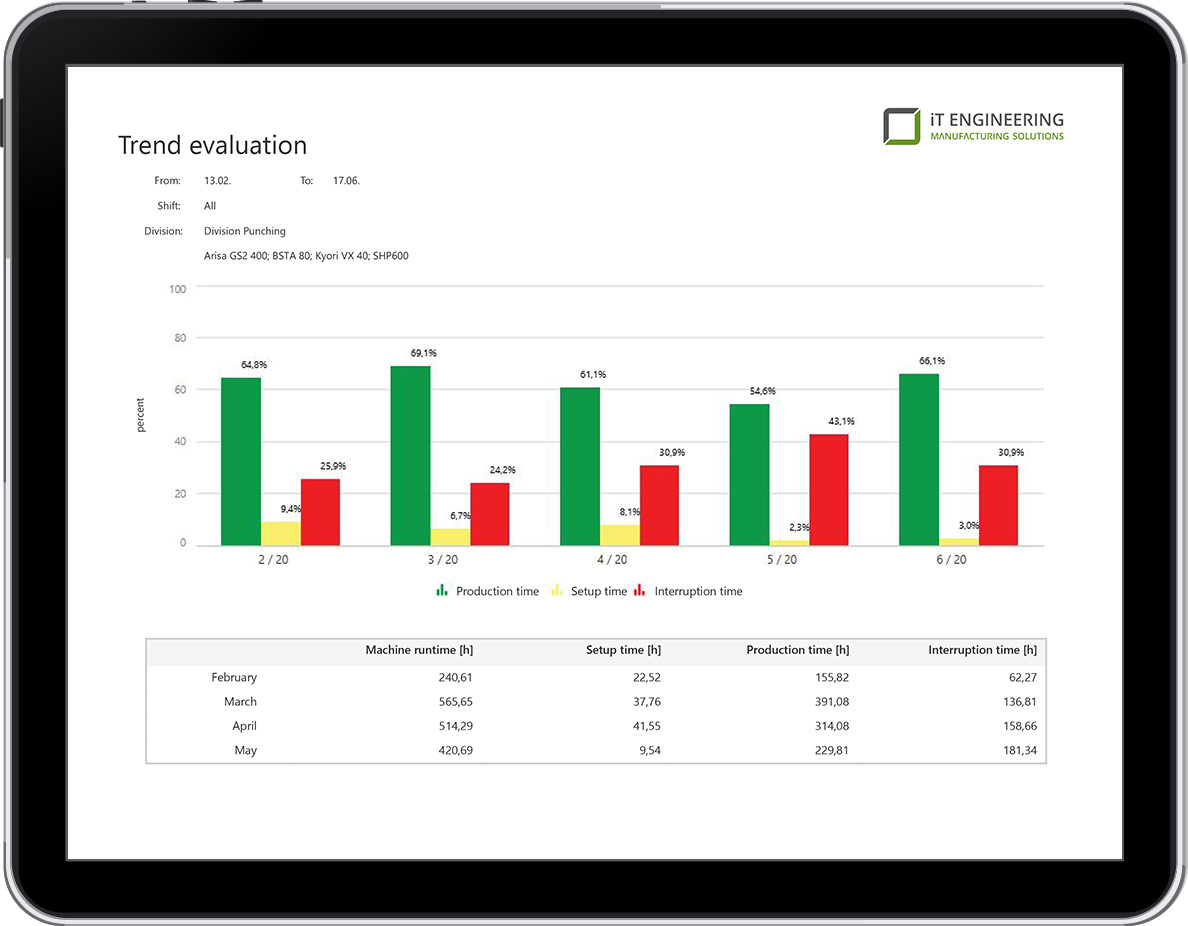

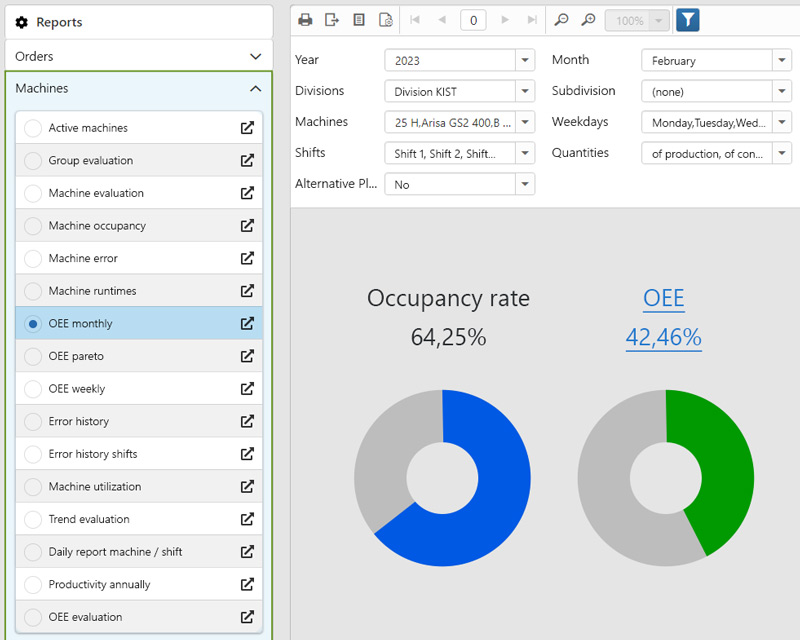

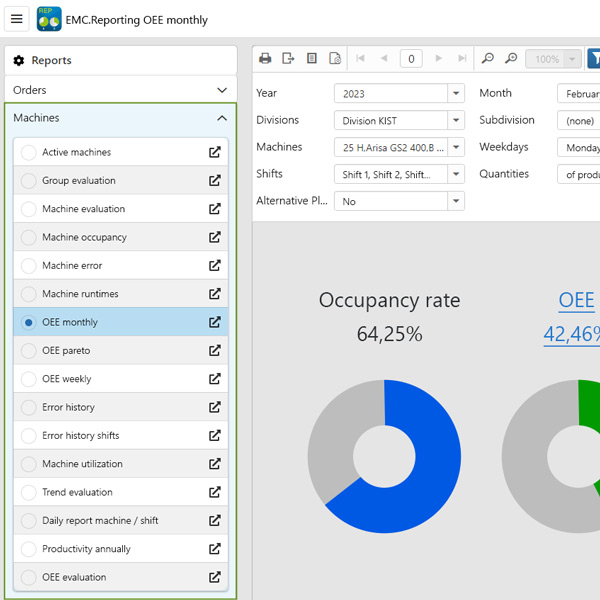

EMC Reporting makes process key figures clearly available for the operational short-term area for the immediate safeguarding of production. This also includes analyses for the strategic long-term area to evaluate the effectiveness of decisions made. Risks and potentials are quickly identified with important analyses such as OEE of plants, setup degrees, downtimes of plants, planned/actual time analysis of articles or productivity key figures. The basic module of our MES Software EMC thus enables an honest performance analysis and process optimization production based on profound data.

Performance analysis with KPIs from production for analyses and reports with real-time key figures

The systematic execution of analyses and evaluations with the system reports shows cause and effect in process management. Give your employees the opportunity to analyze their data, gain important insights and make better decisions.

Key production figures, visualized via analyses and reports, make success measurable.

iT Engineering Manufacturing Solutions GmbH

Process analysis and process optimization for everyone in the company

Every employee can use the report released for him and make analyses such as OEE of equipment, setup degrees, downtimes of equipment, planned/actual time analysis of the articles or productivity key figures.

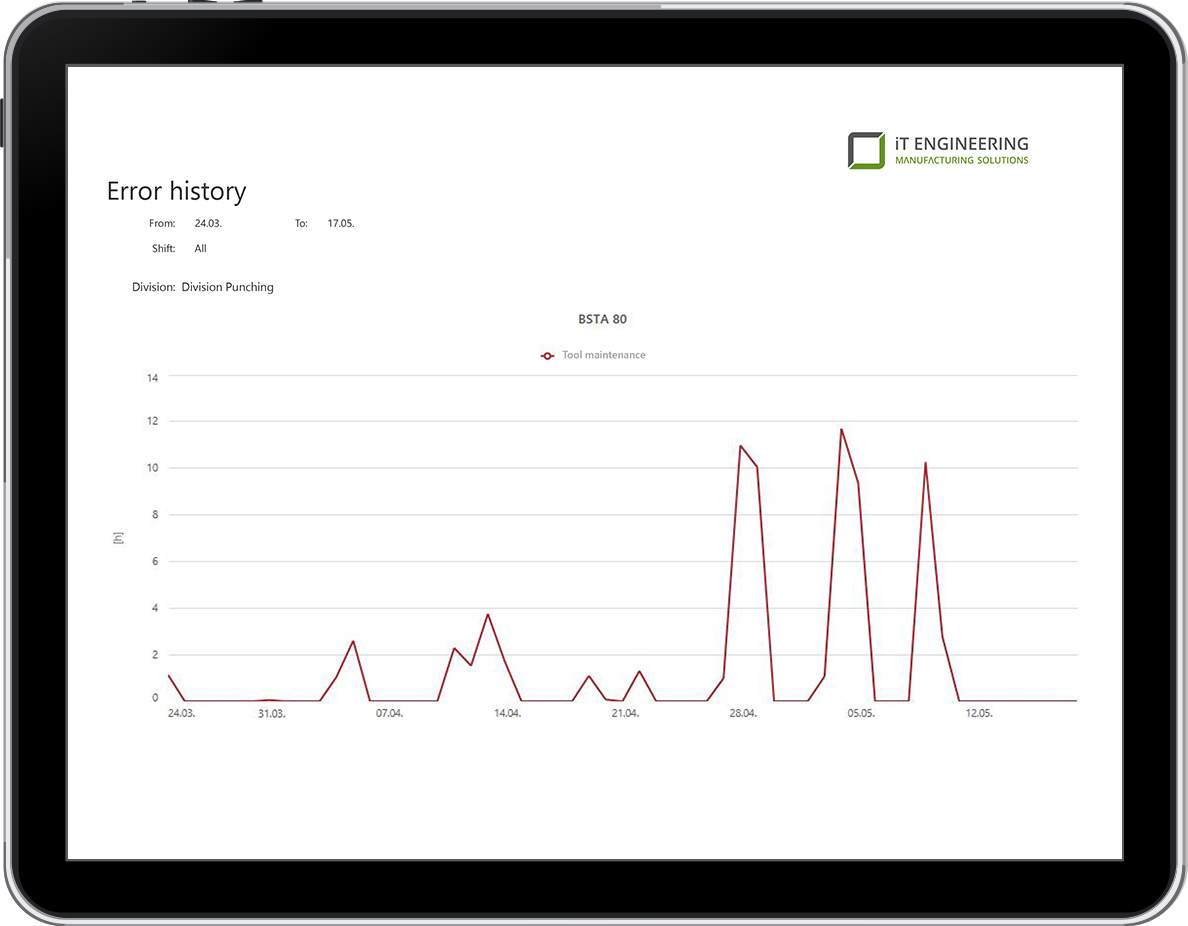

Exact machine running times and setup, production and interruption times complete the all-round view. Weak spots can thus be quickly identified and enable the targeted use of optimization measures.

Analyses and reports: meaningful and clear

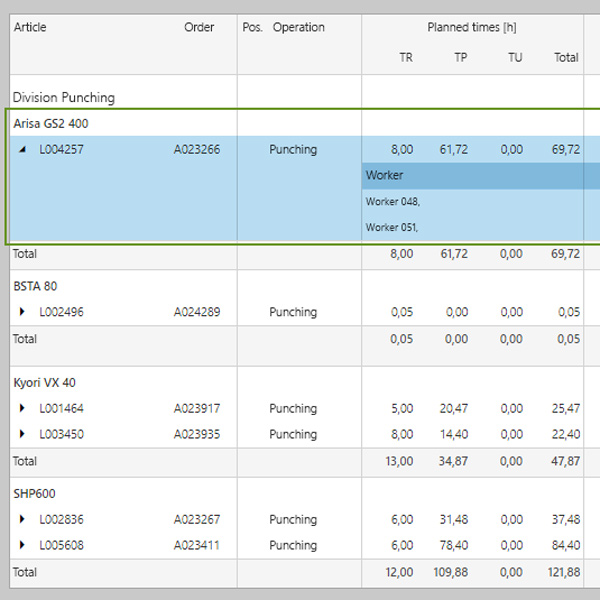

With the drill-down analysis you get deeper insights to consolidated values without overloading the report with a lot of information.

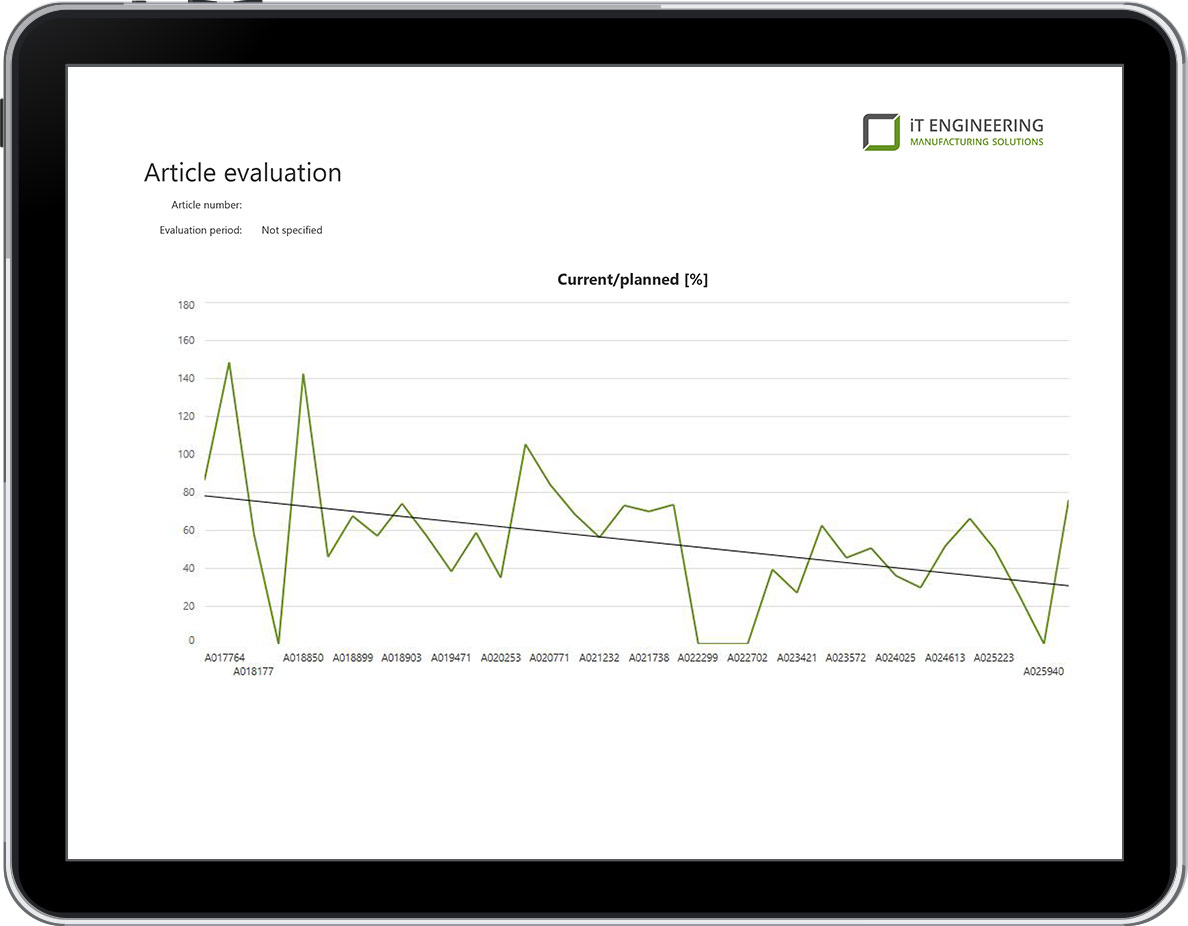

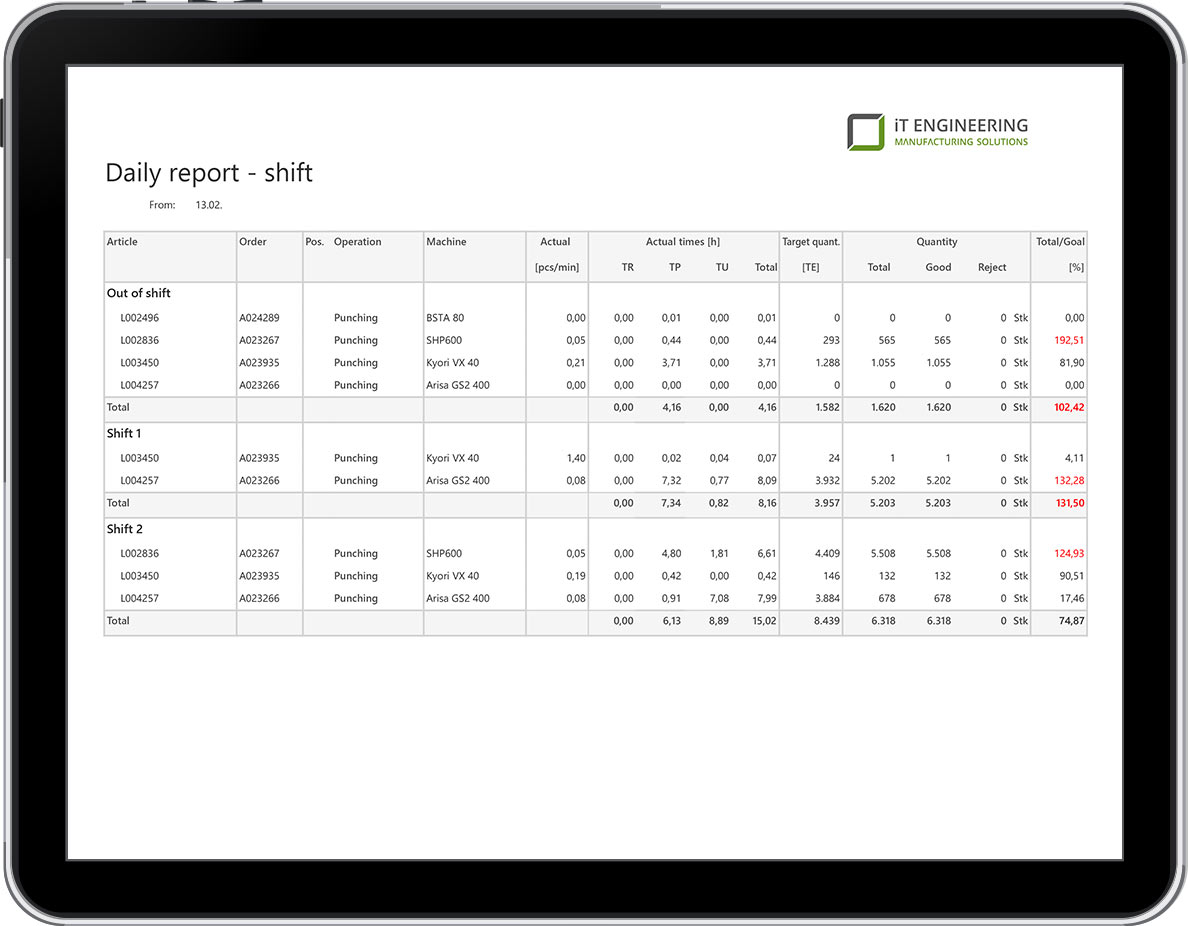

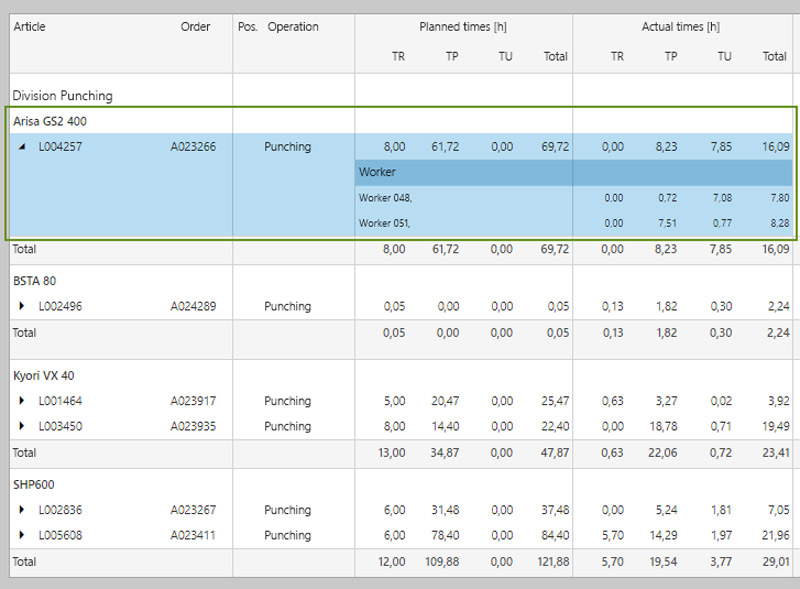

In addition to the machines, the EMC Reporting module offers a variety of other evaluations, such as for individual articles. The comparison of planned and actual time per operation quickly points out deviations. In the detailed view, all evaluated individual orders are listed. For each order, the planned/actual times and quantities are listed with details of the operation and the respective machine.

Simply analyze the cause

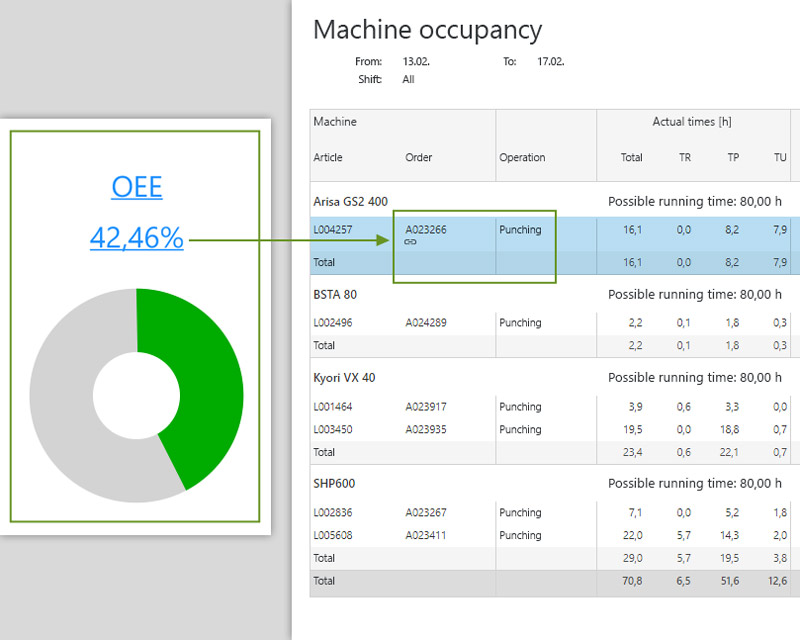

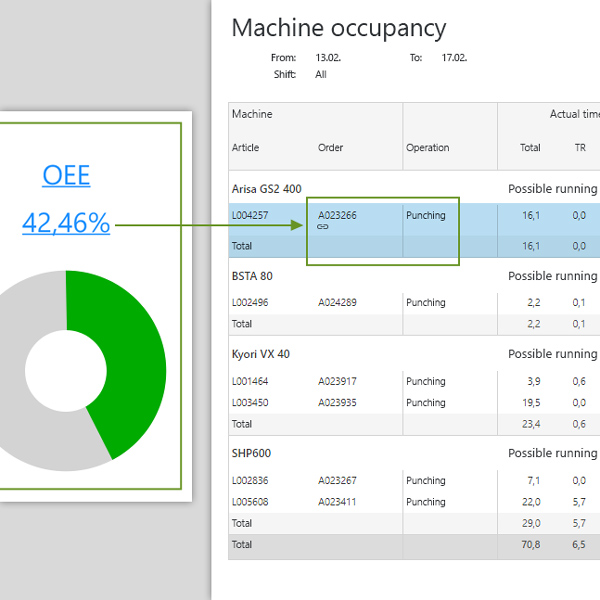

Quickly see supplemental metrics with Linked Reports, such as which jobs are causing the machine’s OEE.

Company-specific analyses and reports

In addition to system reports, use the EMC Report Server module to create specific reports tailored to your company, or integrate reports from external servers such as Microsoft SSRS or SharePoint.

All modules: