Smart energy management

on the shopfloor

Acquire, visualize and analyze energy values reliably

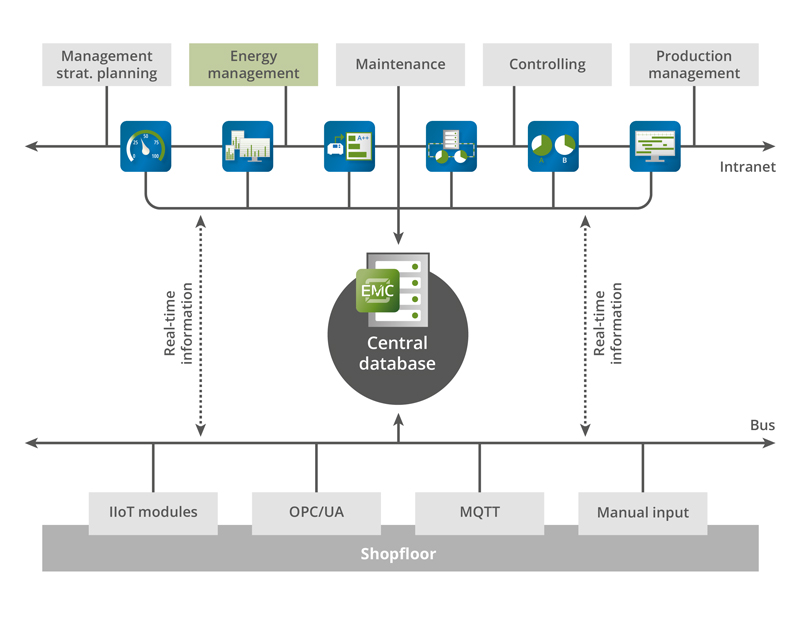

With the EMC Energy Management module and efficient IoT hardware, you can quickly identify energy-intensive processes on the shopfloor. Solutions for optimization can be easily derived. In addition to the energy consumption of machines or peripherals, the MES Software EMC also records the energy consumption of production quantities down to the individual manufactured item. From this, for example, the product-specific carbon footprint can be reliably determined by recording and documenting the energy output per product and operation.

EMC Energy Management meets the requirements of DIN ISO 50001 for energy management systems. It supports the targeted implementation of energy-saving measures. This enables future production processes to be planned in such a way that they are as energy-efficient and cost-saving as possible.

Reliable acquisition, evaluation and visualization

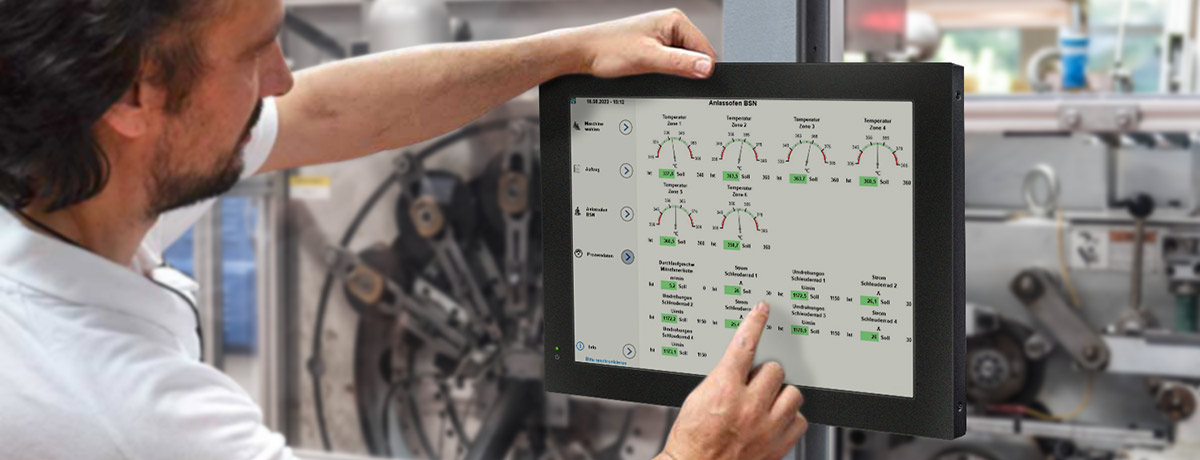

All recorded energy values, directly from the machines or via special IIoT hardware, converge in the EMC Energy Management module. This means they are integrated in the system of the MES Software EMC and can be retrieved – in the portal, on the dashboard or at the MES terminal.

Through the correlations between energy data and the data from machines, production, articles and orders, valuable insights and potential for improvement can be derived across many areas.

Acquisition based on existing infrastructure

With the existing MES, the basic infrastructure is already in place. This means that it is already possible to determine how long the respective operation has been on the machine and how many parts have been produced or processed during this time on the basis of the order logon and logoff. We assign the kWh consumed to this data.

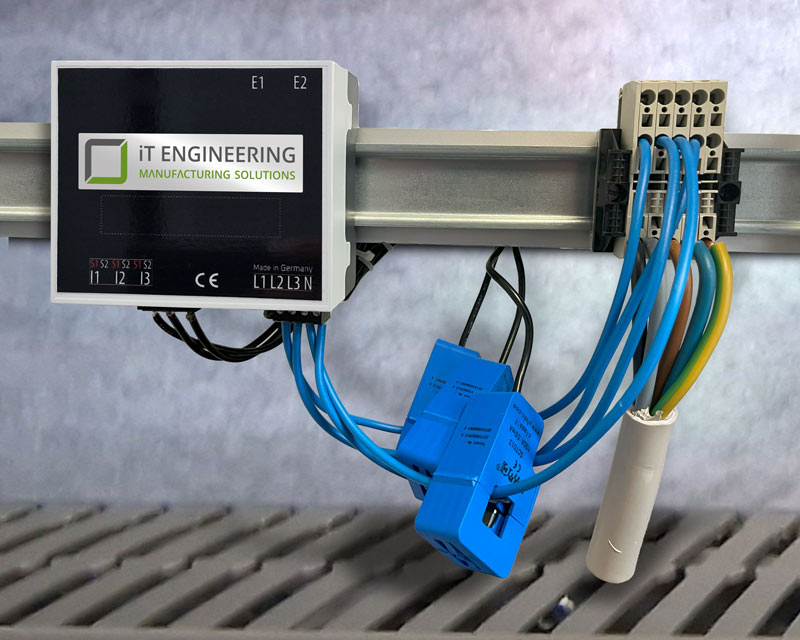

For machines with OPC/UA interface, the acquisition of the energy consumption is possible without additional acquisition hardware. The power consumption is read directly from the control system. For existing machines without OPC/UA interface there are several possibilities for measuring the energy. For this purpose, we use the EMC.IIoT Smart Meter hardware, which reliably measures the energy consumption and reports it back to the MES Software EMC.

Use of modern IIoT hardware

We use modern IIoT hardware (Industrial Internet of Things) for data acquisition. Data exchange takes place via networks, WLAN or a web server.

The measurement of energy is contactless via current terminals, which can measure all important data such as currents and voltages via several inputs. Furthermore, in addition to current measurement, other processes such as temperature, pressure of equipment, etc. can be recorded.

Integration into other energy management systems is possible via MQTT and REST interface.

Simple evaluation and formation of energetic key indicators

The processing and documentation of current and voltage enables a holistic use of the recorded energy values. From the recording directly at the inventory machines, to the evaluation of the consumption and the visualization online.

A large number of relevant energy performance indicators (EnPIs) can be determined and displayed. In addition to absolute energy consumption in production or electricity consumption per reference variable, you can also easily and reliably determine specific energy consumption such as the Product Carbon Footprint (PCF).

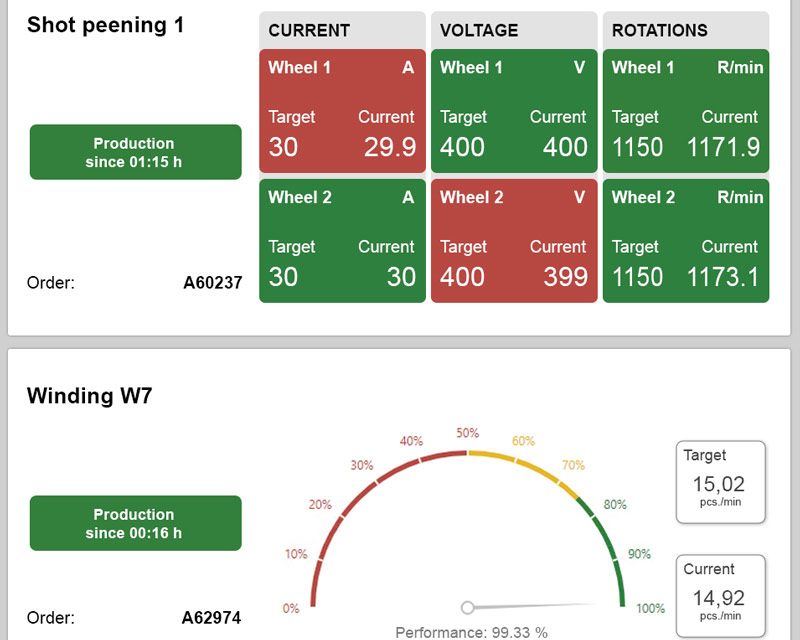

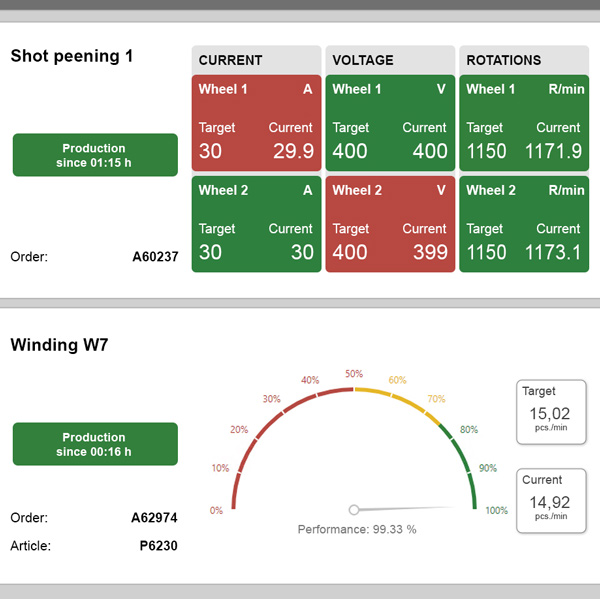

Real-time energy monitoring

The recorded energy values can be visualized easily and clearly via freely configurable dashboards. The display takes place in real time through direct access to the machine or the IoT. It is also possible to include other energy-relevant data from other modules of the MES Software EMC in the energy monitoring for the visualization. This enables far-reaching monitoring of the current energy consumption and helps to make quick optimizations.

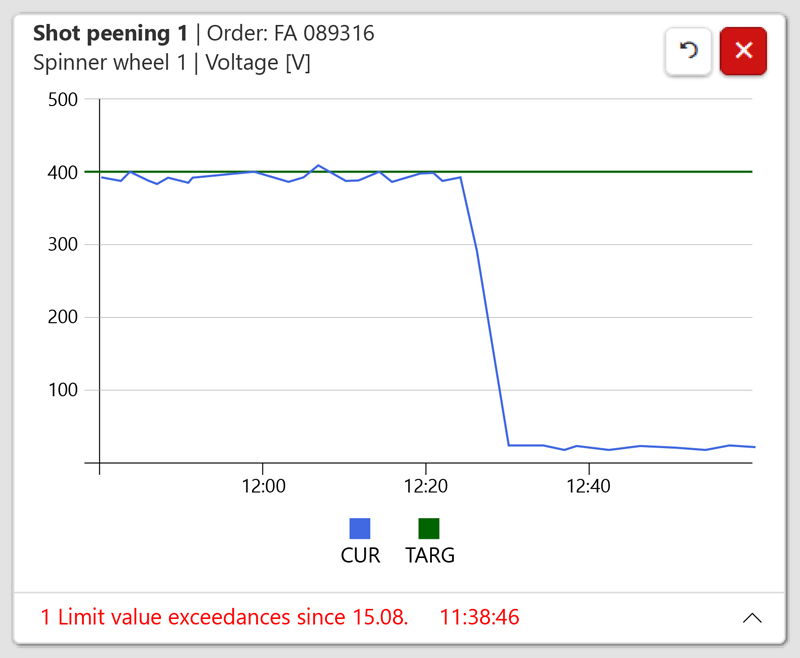

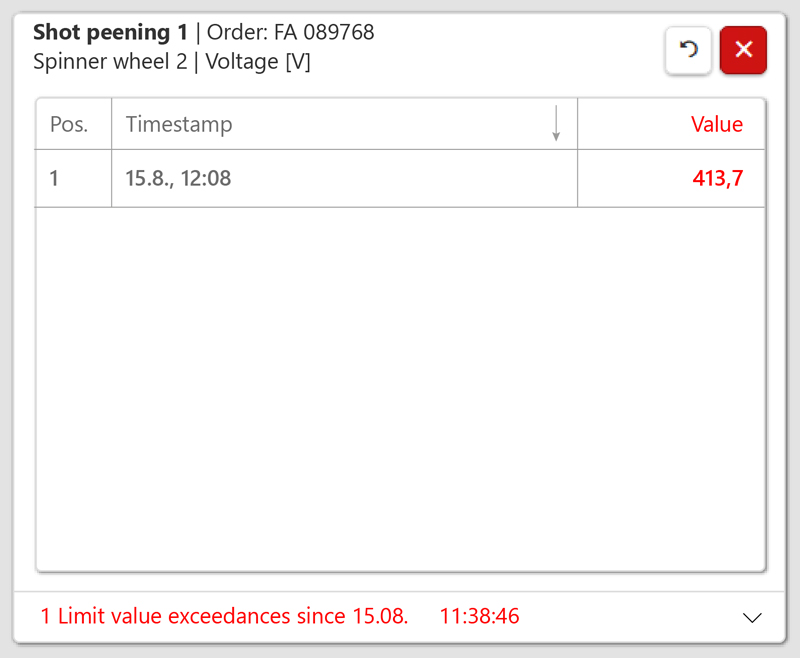

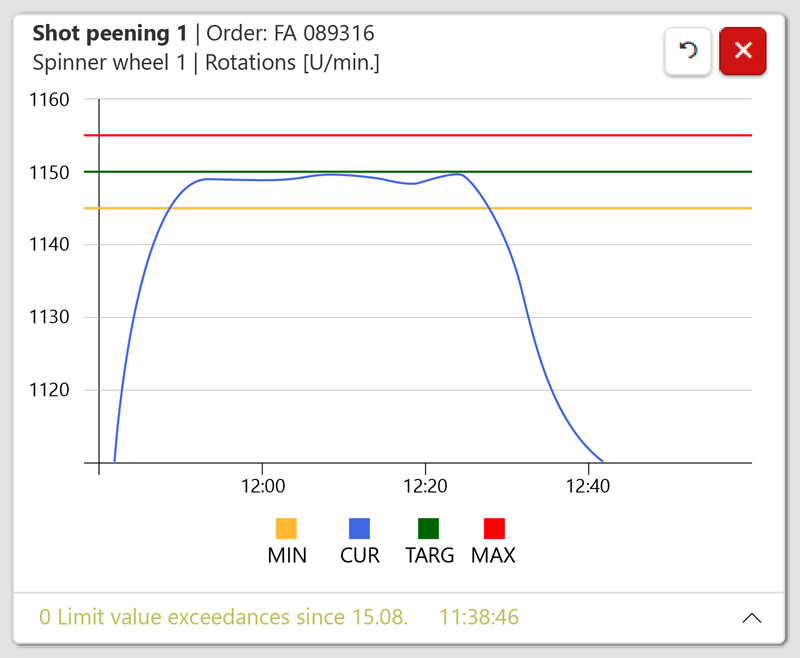

Energy data

The clear representation and visualization of the energy process data in real time. It serves as a basis for the evaluation and analysis of the energy values. In this way, limit violations or unnecessary energy consumption due to downtimes can be identified clearly and precisely in terms of time.

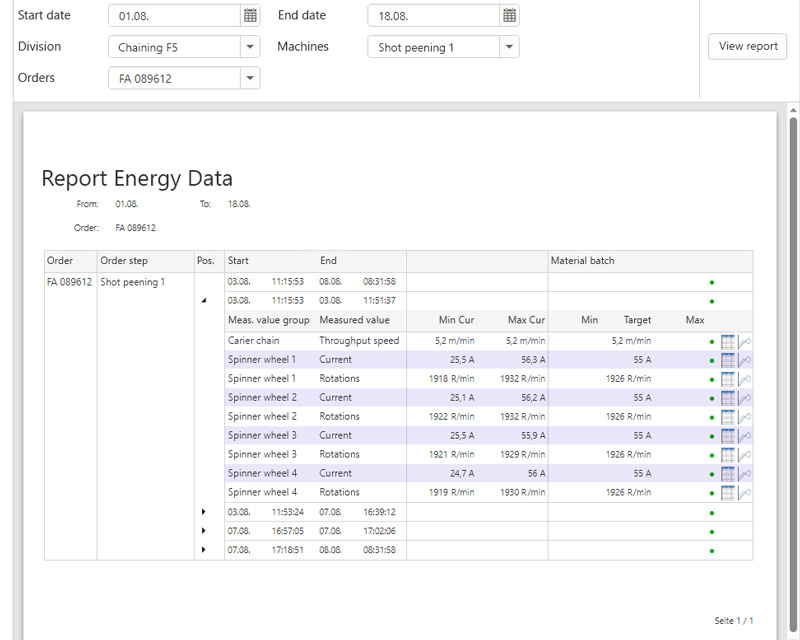

Reports with energy data

Create and send various energy reports easily with the smart features of the MES Software EMC. With just a few clicks you can generate, for example, a monthly report or a report with the representation of the long-term and short-term consumption development.

All parameters such as the time with start and end time, the department or the orders can be selected individually. A large number of reports, each with different parameters, the energy values and correlations, can be reliably created and evaluated via the report server. In addition, further linked reports can be displayed with just one click. For example, tabular listings of the recorded energy values.

All modules: