Acquire and monitor process data

Analyze and document digitally,

easily meet CQI standard

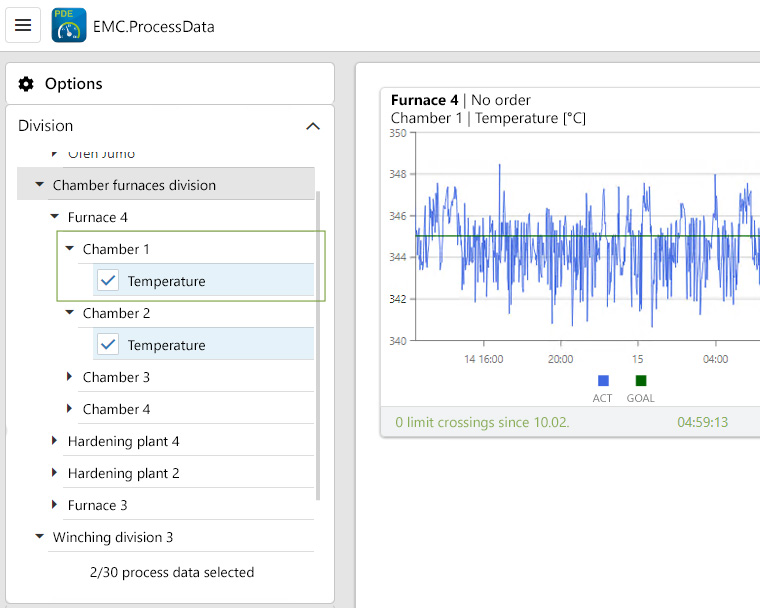

Effectively acquire and monitor process data with the EMC Process Data Acquisition module. It makes the information that accumulates within a process, such as temperature, pressure, energy, etc. … usable. Visualize and document the deviations in the process. Evaluate the process parameters to the order or to the article in larger time periods.

The linking of process values with machine and order data as well as the consideration of process sequences create the necessary prerequisite for transparent traceability and holistic analysis and process monitoring of production.

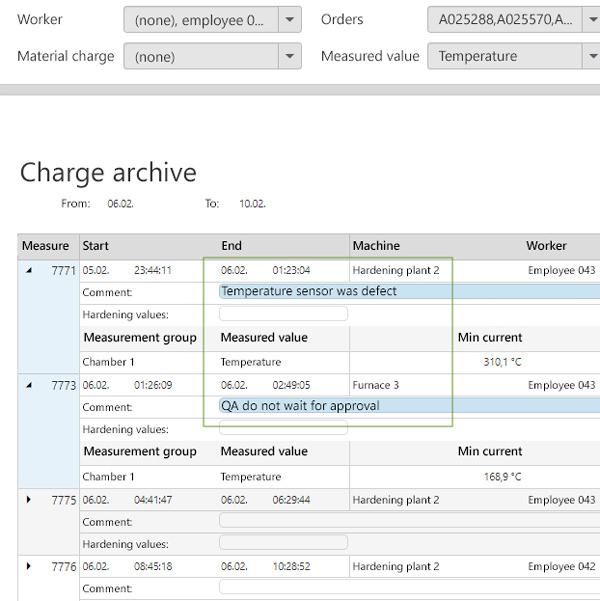

Traceable to the order

Easy access to the process data with the production number. The quality of your processes is transparent and archived in the module of the MES Software EMC through the automated recording.

Automated process data acquisition and monitoring

Values such as actual and target data, tolerances, throughput or holding times can be defined and read directly from the controller via OPC/UA or ModuBus. With an IoT gateway, the values can be read directly from sensors such as thermocouples.

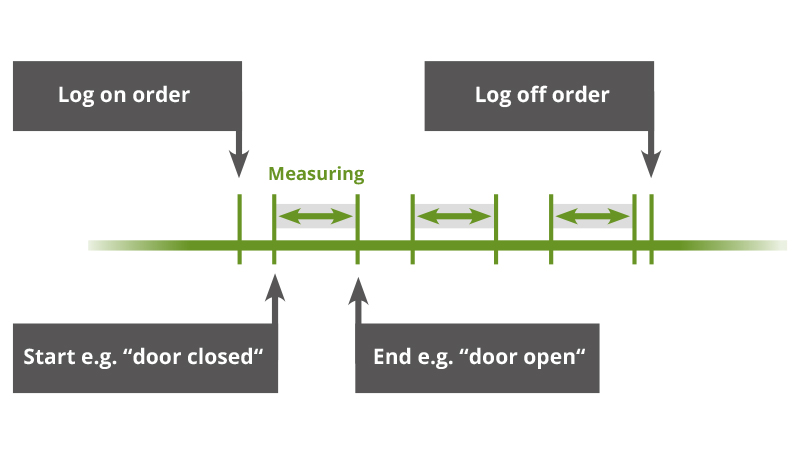

Take process flows into account

Process data acquisition is more than just collecting cyclical data. Data that is not relevant to the process leads to error analyses and must not be recorded.

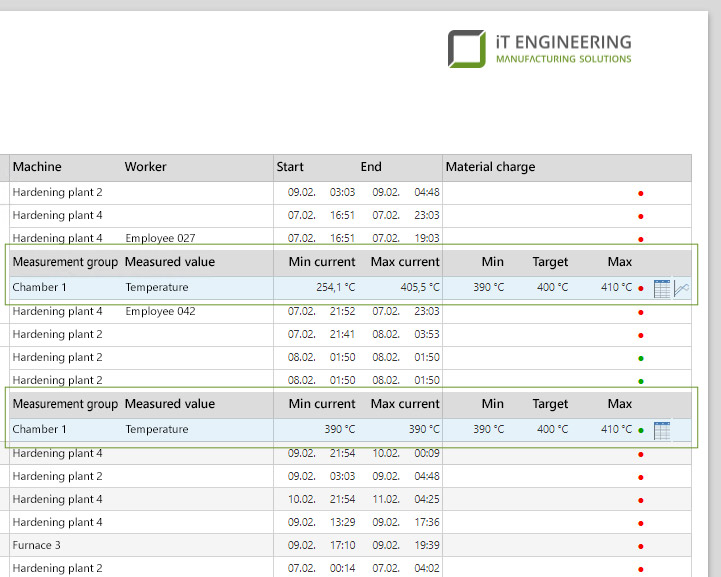

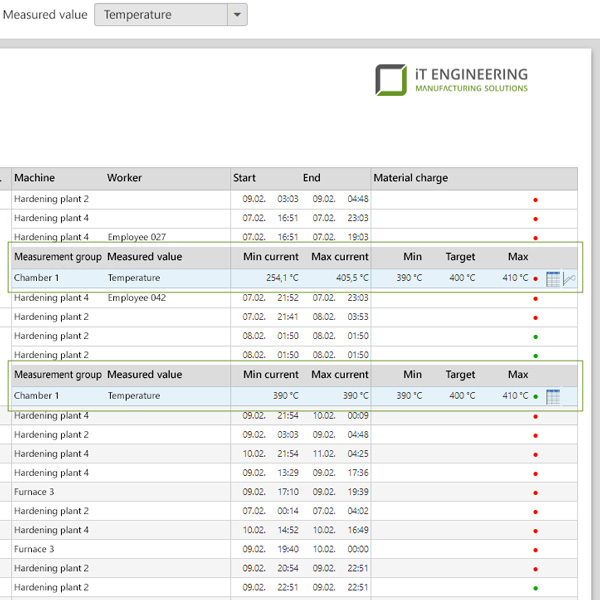

Condense data

Condensing data into information provides an overview of the processes and enables effective process analysis. Critical processes can be quickly identified and checked.

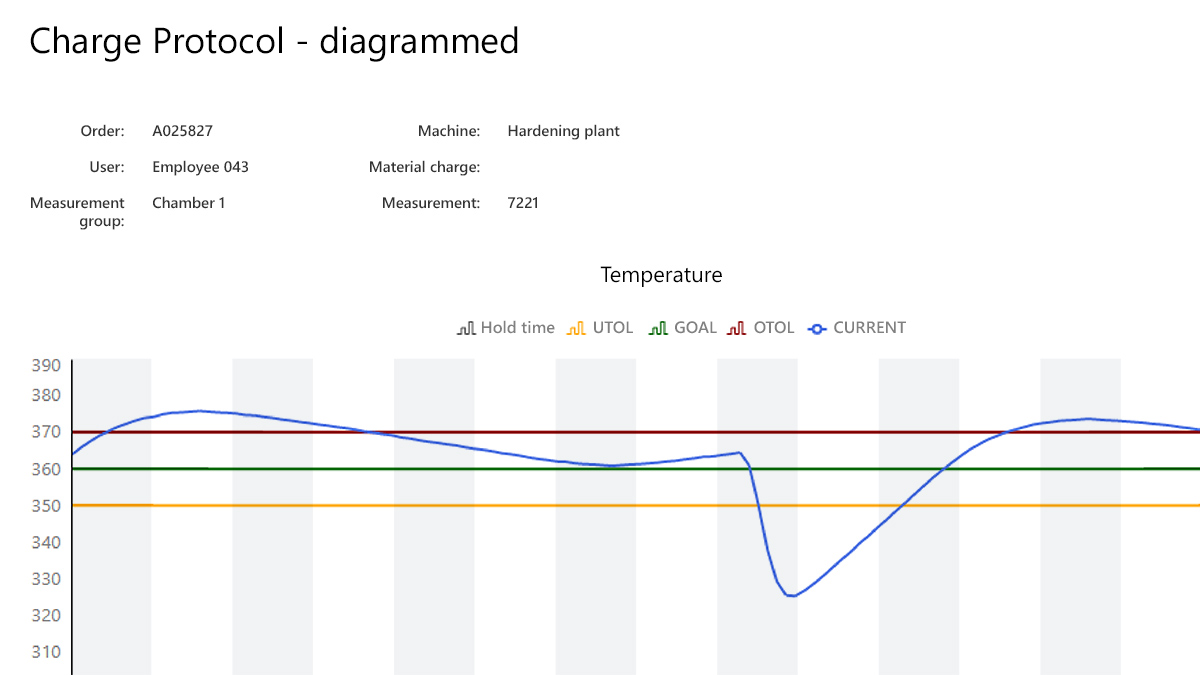

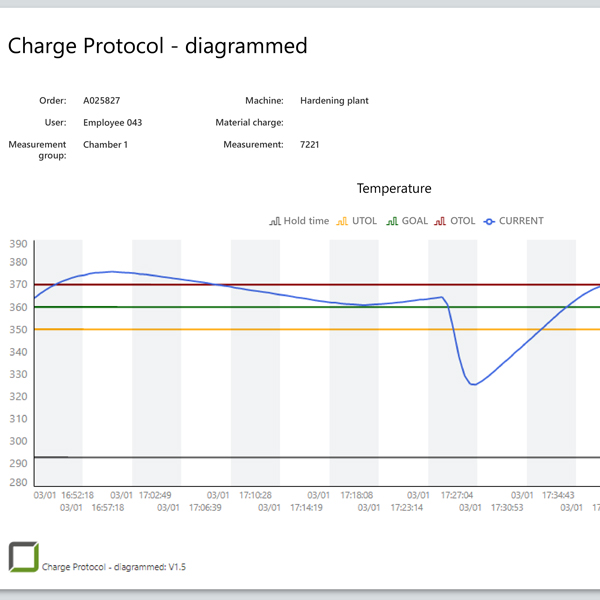

Order- and article-related process data, such as temperature data, are managed and can be evaluated by means of clear reports. This makes it easy to monitor the tempering process. The temperature curves are transparent and can be traced at any time.

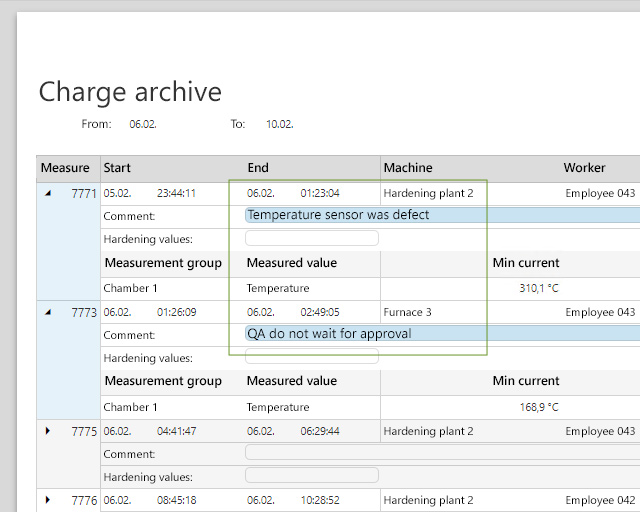

Comment on analyses

Simply write your comment on the process analysis. This comment is transparent for everyone, visible and replaces the handwritten notes. This is especially crucial in the process quality management.

All modules: