And how can pre-defined maintenance and repairs be taken into account and properly scheduled?

Proper planning of machine utilization is immensely important for efficiency and productivity. And one of the biggest challenges in production is keeping the machines running and thus avoiding production delays.

Rough planning with orders from the ERP assumes infinite production capacity. However, what happens live in production, e.g. during a repair or maintenance, does not initially influence this rough planning. In many places, this is done using Excel lists that are laborious to maintain, which have to be corrected daily and constantly reconciled. The effort involved is enormous and the sources of error are high.

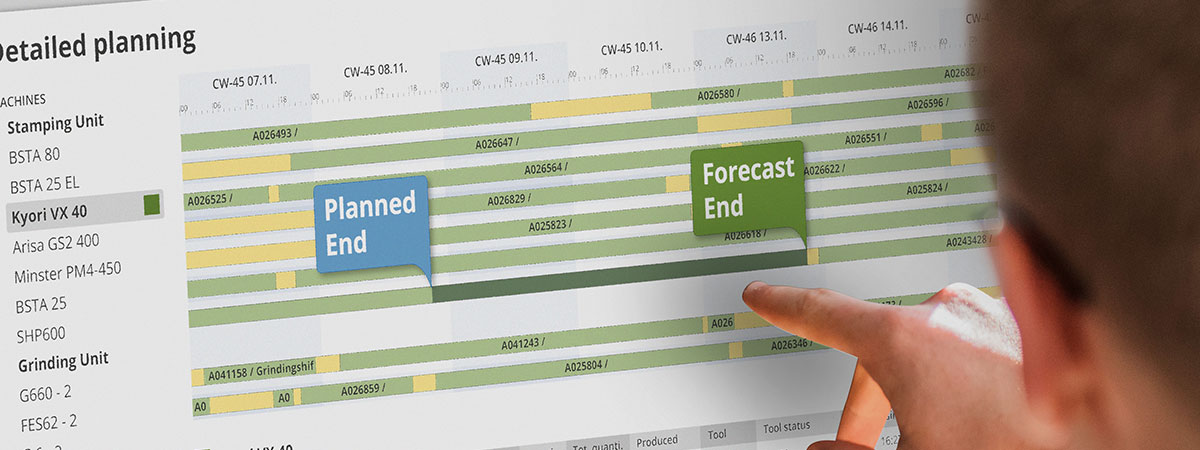

This is not the case in the digital factory. Thanks to the direct connection to the machines, the detailed planning of machine allocation always takes into account real-time data directly from production. This means that if the machine stops, for example if a tool breaks, the planning automatically adapts and reliably reschedules follow-up orders. Pre-defined maintenance and repairs are also taken into account and scheduled correctly. This makes machine utilization much more realistic and dynamic.

The most important benefits of planning machine utilization with real-time data are

- Higher machine availability

- Less downtime and faster response

- Maintenance and servicing are scheduled automatically

- Better utilization and capacity utilization

- Better interaction between planning, production and toolmaking

Machine allocation planning with direct connection to the machine

Realistic production planning for machine utilization is the be-all and end-all. This is made possible by the direct connection to the machines. The roughly planned orders are received by the ERP and supplemented and adjusted in short-term planning with the data collected in real time on the shop floor (machine occupancy, tool allocation, employees or downtime reasons). The work processes for the orders are then planned for the individual resources (machines, workstations).

Bye-bye printed planning lists

Planning in digital production makes printed production lists and their distribution in production superfluous. This means that the current plan sequence is displayed directly on the MES terminal and in the shop floor dashboard. In addition, the order is registered directly via the displayed planning list.

Navigation function automatically adapts the planning to the current order progress of the machine

The actual progress is continuously reported back to the planning system after the start of the order on the machine – in real time. The planning is then updated automatically, carries out a forecast calculation for the end of the order and updates the start date of the following orders.

In addition, predefined machine or tool maintenance is automatically taken into account in the machine document planning and the planning is adjusted accordingly.

Optimum machine maintenance

It goes without saying that machines need to be regularly serviced, checked and maintained. This has a lasting effect on the quality of your own production and ensures that the machines run smoothly. The EMC Maintenance module makes it easy to neatly file and document important machine maintenance.

Instructions, maintenance steps or special maintenance instructions can be stored for each machine and peripheral equipment – both automatically and manually. In addition to the individual maintenance steps to be carried out, maintenance cycles (daily, weekly, monthly, annually, etc.) can also be defined individually. Typical checks or maintenance tasks, such as a grease change on the gearbox, are also created as maintenance tasks and can therefore be easily carried out and documented as required.

The system continuously checks the status of the machines and reports upcoming maintenance. If maintenance is due, it can be started simply by scanning a QR code attached to the machine, for example.

Digitalized tool maintenance

With the EMC Maintenance module, you can carry out maintenance, repairs and servicing, including all components and spare parts used, both manually and according to individually predefined maintenance cycles. This enables high technical availability and reliable maintenance.

Produce and plan more efficiently with the integration of tool maintenance

The digital information exchange and access provided by the MES Software EMC enables predictive control of individual production processes. For example, in the event of a repair, the tool shop is informed directly from the machine terminal. This information is also sent directly to production planning without any detours.

This means that the planner knows the current tool status at all times. Upcoming maintenance and current repairs are automatically integrated into detailed planning. This ensures realistic and smooth production processes. In addition, the tool shop receives information from the planning department about which tool is needed when and what maintenance is due.

Complete and comprehensive documentation of maintenance and repairs

All machine maintenance, tool maintenance and repairs are documented in the digital life cycle card of the MES Software EMC. The current status, availability and history of the tools are also stored in the digital tool card.

Further information such as articles and orders are linked. Installed spare parts and their number can be traced exactly.

The complete workflow for digital maintenance management can be called up digitally at any time, directly at the machine terminal or via mobile tablets. Maintenance can be started easily either manually via the portal of the MES Software EMC or by scanning a QR code attached to the machine or tool.

Conclusion

There will always be delays in production and they are difficult to avoid. How these are dealt with and what measures are taken to reduce them makes a decisive difference to how well planning works and therefore how productive and efficient production is.

Resource-optimized planning with the integration of real-time data from production and properly scheduled maintenance ensures that unnecessary downtimes are avoided and that accurate forecasts for completion and follow-up orders are obtained. The digitalized maintenance of machines and tools ensures that maintenance can be better planned and fully documented. This interaction ensures that machine utilization planning is always up-to-date and dynamic.

Contact us

Do you have further questions about how to plan your machine capacities more efficiently with our MES Software EMC or about implementing your digital factory?

We will be happy to advise you and provide you with a personalized offer.

Simply call us on +49 7127 – 9231 10 or send us an e-mail to info@ite-ms.de

Frequently asked questions about machine occupancy with real-time data

Why is machine utilization often planned imprecisely?

Many plans are only based on rough ERP data and do not take into account short-term downtimes, set-up times or maintenance. Real-time data helps to close these gaps and adapt plans to reality.

How can real-time data improve machine planning?

Real-time data makes current machine statuses, tool breakages or unplanned downtimes immediately visible so that the production plan can be adjusted automatically. This reduces downtime and idle times.

What advantages does an MES system offer in detailed planning?

An MES system integrates real-time data into detailed planning and ensures transparency in machine utilization. It helps to identify bottlenecks, schedule maintenance and avoid breakdowns.

Is it worth integrating maintenance data into planning?

Yes, because maintenance often comes as a surprise and disrupts the plan. By integrating maintenance data, maintenance can be planned without unnecessarily disrupting production.

What role does the automatic adaptation of machine planning play?

The automatic adjustment of machine utilization planning means that the production plan is constantly updated based on current events such as malfunctions or maintenance. This means that the plan remains realistic and resources are used optimally.