And how can waiting times and waste be identified and reduced through digital processes?

In many manufacturing companies, everything seems to be fine: despite the ongoing economic downturn, the “units per minute” indicator actually looks good. But productivity is falling. And unit costs remain stubbornly high or are even rising.

This is precisely where the unit cost trap snaps shut: the focus is almost exclusively on production speed, while waiting times, repair loops, and coordination efforts are growing unnoticed in the background. For many years, experts have been pointing out that in discrete manufacturing, it is not the actual processing time that determines success, but losses in the flow of information and materials.

In this article, we show how a close look at the mean time to repair (MTTR) of tool repairs in the production process reveals where waste occurs and how MES Software EMC not only makes these losses visible, but can also significantly reduce them. The digital networking of production and toolmaking is crucial here: only when all parties involved can see what is happening on the shop floor in real time can waiting times and waste be consistently reduced, thereby lowering unit costs in the long term.

The most important benefits are:

- Significant reduction in unit costs through consistent reduction of waiting, searching, and coordination times related to malfunctions and repairs

- Transparent MTTR evaluations as a basis for improvement processes

- Faster response times in toolmaking because repair orders are started directly at the MES terminal and transmitted in real time to the responsible teams

The unit cost trap: When “more output” does not automatically mean lower costs

Many companies still manage their production with a simple question: How many parts can we produce per minute? While this may sound logical at first glance, it ignores important cost drivers. Thanks to modern machines, automation, and optimized programs, pure processing times are often already very efficient today. The real costs arise when nothing is being produced. In other words, during times of:

- Unplanned downtime

- Lengthy repairs

- Coordination rounds between production, AV, and toolmaking

- Missing information and approvals

This is exactly where a modern MES such as EMC comes in. It shifts the focus from “How fast is the machine running?” to “Where are we losing time in the overall process?” and thus paves the way for real reductions in unit costs.

MTTR in detail: How waiting times inflate repair times

A key lever for this is the Mean Time To Repair (MTTR) metric. At first glance, it appears to be purely a maintenance metric. In fact, it is an excellent indicator of how well your processes relating to malfunctions and repairs are organized.

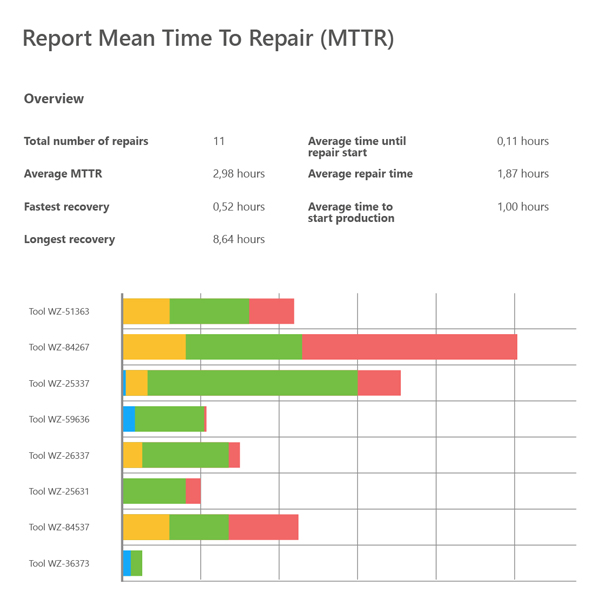

In the MTTR report of the MES Software EMC, the repair process is divided into three phases:

- Yellow: Time until the repair begins

This is where the organizational effort lies:

How quickly is a malfunction reported?

How quickly does the information reach the tool shop or maintenance department?

Are responsibilities clear, or does everything take a roundabout route?

- Green: The actual repair time

This is the “manual” work on the machine or tool. In many companies, this proportion is surprisingly small, because the specialists work efficiently as soon as they can get started. - Red: Time until production restarts

After the repair, the second major waiting period often begins:

Setup, test run, quality approvals, documentation requirements.

Unclear information, lack of material supplies, or coordination between shifts and AV prolong the phase in which the machine could be running again but is not yet doing so.

The MTTR chart shows that it is not the repair itself (green) but the yellow and red phases that drive up losses. These times hardly appear in classic productivity metrics, but they have a major impact on unit cost accounting.

How does the MES Software EMC make waiting and loss times visible?

To ensure that MTTR analysis is more than just a one-time look in the rearview mirror, continuous digital data collection directly on the shop floor is required. This is precisely where EMC plays to its strengths.

All processes and operations associated with the respective event are systematically recorded digitally, similar to a timestamp. This begins with the fault report directly at the machine’s MES terminal. The information is sent directly to the tool shop. This means that the first critical moment, the recording of the fault, is documented clearly and within seconds. Further timestamps are the start and end of the repair or the resumption of production.

These timestamps are used to automatically calculate the three phases of the MTTR and visualize them in the form of a report.

Transparent dashboards for all stakeholders

In addition to reports, the recorded data can also be displayed on clear dashboards. This allows:

- Production managers to see which machines are idle due to repairs, maintenance, etc.

- Maintenance/toolmaking to see where repairs need to be carried out and where maintenance is due.

This turns an abstract key figure into a concrete picture.

Networked processes: Production and toolmaking in one system

The real impact comes when processes are also networked with each other on the basis of this transparency. With EMC, the entire repair process can be digitally mapped from start to finish.

- Start repair orders directly at the MES terminal

In the event of a malfunction, the operator starts the repair order directly at the terminal. Instead of a phone call or email, a digital order is created that contains all relevant machine data, clearly references the affected tool, and stores the priority and type of malfunction. - Immediate information for toolmaking and maintenance

The repair order appears in real time in the toolmaking or maintenance dashboard. All open repair orders are displayed there with their status in real time. This drastically reduces the yellow phase (“time until repair begins”): Toolmaking no longer has to “call after the fact,” but can schedule specifically and react immediately. - Feedback and restart without media discontinuity

Once the repair is complete, the person responsible also reports the status back to the MES: repair completed, machine ready for setup, any notes to production or quality, automatic documentation for traceability and audit evidence. Production can immediately see in the dashboard that the machine is available again and can continue with the order. This also consistently reduces the red times (“time until production start”).

The result: shorter downtimes, more stable throughput times, and measurably lower unit costs. Not by “turning faster,” but by smarter processes.

From a focus on key figures to holistic production control

Anyone who has experienced how much yellow and red time disappears in the MTTR diagram will fundamentally change their view of production. Instead of simply increasing output, the focus shifts to avoiding waste. Decisions are no longer based on gut feeling, but on clean, timely data. Improvement measures can be targeted where the greatest losses occur, whether in tooling response times, approval processes, or setup management.

EMC supports this change by bringing together data from machines, terminals, and planning systems, providing context for key figures such as OEE and MTTR, and giving those responsible on the shop floor and in management the same, up-to-date information. Step by step, this creates a digitally networked production system in which unit costs are no longer “estimated” but can be influenced in a transparent and reliable manner.

Conclusion

The unit cost trap snaps shut when companies focus solely on the number of units per minute and ignore how much time is lost in the background. Analysis of the mean time to repair (MTTR) shows that it is not the actual repair that is the problem, but the waiting and coordination times before and after. This is exactly where digitalization and MES come in.

The digital networking of production and toolmaking makes it possible to digitally record malfunctions directly on the machine and inform the toolmaking department in real time. The reduced response time ensures quick intervention and implementation, so that the machine can resume production more quickly. This systematically reduces waiting times and thus lowers unit costs in the long term. It is always worth taking a closer look beyond “units per unit of time.”

Contact us

Would you like to learn more about how you can sustainably reduce your unit costs with our MES Software EMC?

We would be happy to advise you and provide you with a personalized quote.

Simply call us at +49 7127 – 9231 10 or send us an email at info@ite-ms.de

Frequently asked questions about unit costs and how to reduce them

What is the cost per unit trap in discrete manufacturing?

The cost per unit trap describes a situation where the KPI “parts per minute” looks good, but productivity is declining and unit costs remain high or even increase. The focus is too much on processing speed, while waiting times, rework loops and coordination efforts grow unnoticed in the background and drive costs up.

Why is the “parts per minute” KPI no longer sufficient?

Modern machines and automation have already made pure processing times highly efficient. The real costs arise when nothing is being produced – during unplanned downtimes, lengthy repairs, coordination rounds and missing information. “Parts per minute” ignores these losses and therefore only provides an incomplete picture of the actual cost per unit.

What role does MTTR (Mean Time To Repair) play for unit costs?

MTTR shows how well processes around failures and repairs are organized. It is viewed in three phases: time until repair starts (organizational waiting times), the actual repair time, and the time until production restarts (setup, approvals, etc.). It is especially the first and last phase that increase downtime and thus unit costs – not the repair work itself.

How does the MES Software EMC make waiting and loss times visible?

EMC records all relevant events digitally on the shop floor using timestamps: the failure notification at the MES terminal, start and end of the repair, and the resumption of production. From this data, the three MTTR phases are calculated automatically and visualized in reports and dashboards. As a result, hidden waiting and coordination times become transparent and can be addressed systematically.

What concrete benefits does EMC offer for reducing unit costs?

EMC reduces unit costs by systematically cutting waiting, searching and coordination times around failures and repairs. Repair orders are started directly at the MES terminal and transmitted in real time to tooling and maintenance. Reaction times are shortened, downtimes become shorter, throughput times more stable and improvement initiatives can be triggered in a targeted way based on transparent MTTR evaluations.