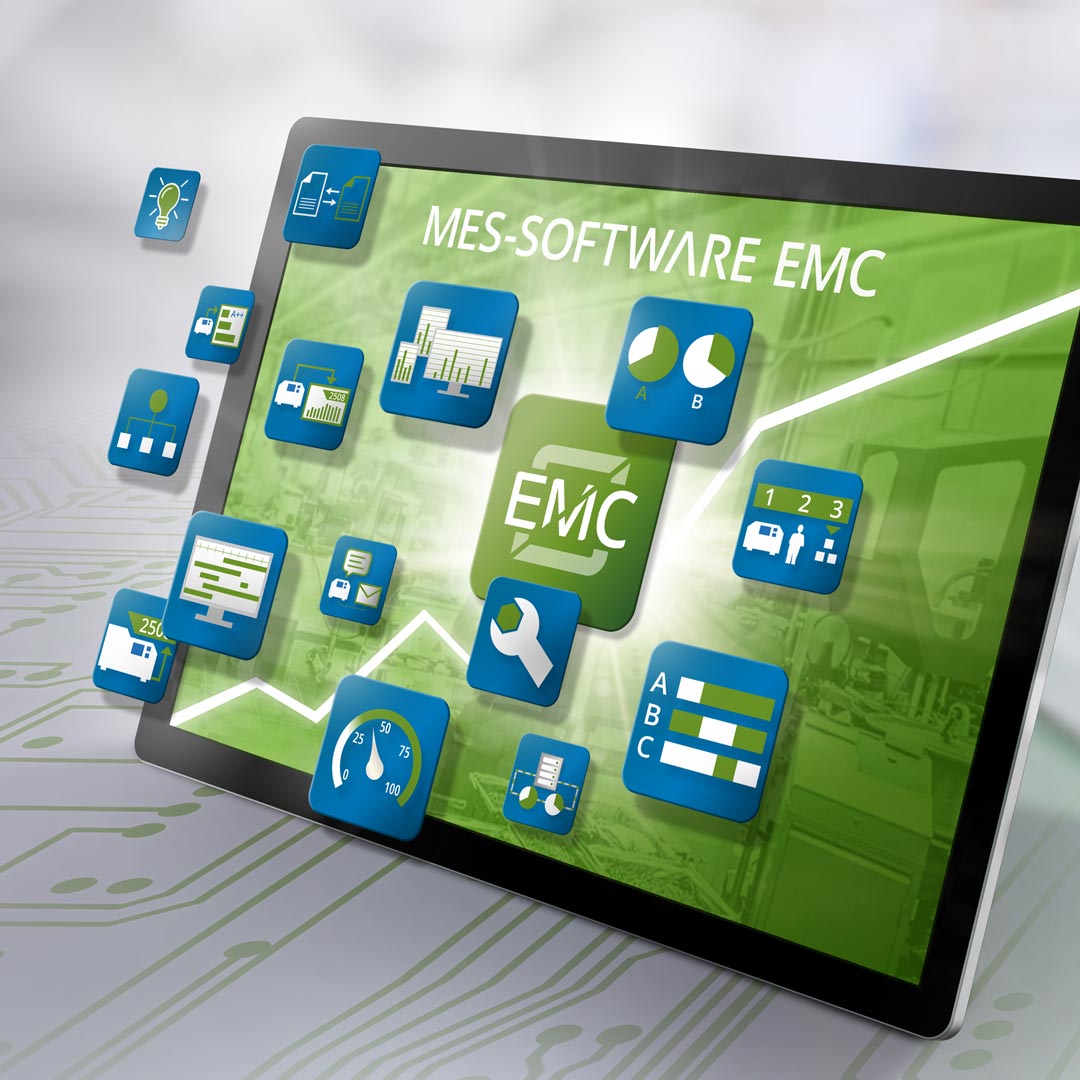

The digital factory with iT Engineering Manufacturing Solutions GmbH

For digitalization that increases efficiency.

With the MES Software EMC that makes it easy.

For digitization that increases efficiency. With the MES Software EMC that makes it easy.

As an experienced partner for digitalization, iT Engineering Manufacturing Solutions GmbH supports you with our smart MES Software EMC in the digitalization of production and its processes on your shopfloor. You monitor, control and optimize your plants and processes in real time. The MES Software EMC is based on an open, modular and service-oriented architecture and integrates seamlessly into the existing IT landscape.

Implementing digital manufacturing successfully

With our smart MES Software EMC, we support you in the digitalization of production and its processes on your shopfloor. It is your guarantee for greater efficiency, productivity and sustainability. You monitor, control and optimize your systems and processes in real time.

Easy. Intuitive. Modular.

The modular architecture of the MES Software EMC offers you the important freedom and flexibility when implementing your future-oriented digital factory – step by step or holistically – individual modules or as a complete system. It adapts completely to your needs, integrates into your existing IT landscape and brings together the data streams from ERP and the shopfloor for your smart production.

Record the status of production orders, automatically in combination with the MDE or by input from your employees directly at the terminal on the store floor. At the same time, you can monitor your orders and the individual work processes.

AUTOMATICALLY

IMMEDIATELY

Dashboards on large-screen monitors directly on the store floor make machine downtimes, reduced speed, quality losses and system malfunctions immediately recognizable.

POTENTIAL

FASTER

Risks and potentials are quickly identified with important analyses such as OEE of systems, setup levels, system downtimes, planned/actual time analysis of articles or productivity indicators.

EFFICIENTLY WITH

NAVIGATION

The navigation function automatically adapts your planning to the current order progress of the machine and visualizes the planned order sequence digitally on the machines.

transparently

This enables better planning and utilization of machines and departments as well as less downtime.

EMPLOYEE

ASSIGNMENT

PLANNING

You can assign your employees to the respective machines in the department according to their predefined skills - completely digitally, without separate shift lists.

PAPERLESS

All documents and information relating to the production of the order are made available for this purpose. Digitally and at the touch of a button, directly on the MES terminal in production or on a mobile tablet.

In addition to the energy consumption of machines or peripherals, the energy consumption of the production quantities down to the individual manufactured item is also recorded.

ENERGY

MAINTENANCE

The complete, digital documentation of maintenance and repairs enables high technical availability and reliable maintenance of machines and systems as well as tools and peripherals.

PARTS SMARTER

This enables more efficient, cost-saving and error-free management of all spare parts.

PROCESSES

For example, if the machine stops due to tool damage, the fault is displayed directly on the dashboard in the tool shop. This allows maintenance to react immediately and rectify the damage.

TRACEABILITY

TRACK SEAMLESSLY

This means that the entire service life of the machine or tool, including spare parts management, is documented in the history and can be traced exactly.

SMARTER

It is quick and easy to determine at any time on which machine, where and when the product was manufactured under which production conditions and where it was ultimately delivered.

PRODUCTION

This significantly increases the quality of production.

COMMUNICATION

Without having to leave the workplace, decisions made, important information or even last-minute changes can be communicated quickly and provide an enormous time advantage.

the Shopfloor

and back

The bidirectional exchange enables every department to work reliably on the basis of the same data and information.

AUTOMATICALLY

IMMEDIATELY

POTENTIAL FASTER

EFFICIENTLY WITH

NAVIGATION

TRANSPARENTLY

EMPLOYEE ASSIGN-

MENT PLANNING

PAPERLESS

ENERGY

MAINTENANCE

PARTS SMARTER

PROCESSES

TRACEABILITY

TRACK SEAMLESSLY

SMARTER

PRODUCTION

COMMUNICATION

THE SHOPFLOOR

AND BACK

iT Engineering Manufacturing Solutions:

Manufacturing know-how meets digital competence

Manufacturing know-how meets digital competence

Around 30 years of experience in the manufacturing industry and in the field of “manufacturing processes” ensure that we, iT Engineering Manufacturing Solutions GmbH, successfully implement your requirements for digitalization in manufacturing. Our MES Software EMC is the leading MES System for the digital factory in the forming industry. Over 3,500 machines have already been successfully connected to our MES solution EMC.

iT Engineering News:

All about the digital factory

All about the digital factory

Yearly update 2026 of the MES Software EMC

Your yearly EMC update 2026 is ready The yearly update [...]

Trade fair Blechexpo 2025 in Stuttgart

The digital factory with EMC at the trade fair Blechexpo 2025 in [...]

Let’s blog: iT Engineering launches blog on the digital factory

Knowledge, impulses and practice for your head start We are pleased [...]