Freshly published: Our latest expert article “Digitalization in manufacturing? This is how it works!” in the current wire 2024 trade fair issue (2/2024) of wire magazine.

In our expert article “Digitalization in manufacturing? This is how it works!” we report on how quickly and easily shopfloor digitalization works with our MES Software EMC. This allows you to simplify and optimize many workflows and processes, thereby increasing your efficiency, productivity and sustainability.

Would you like to find out more about digitalization in manufacturing with EMC?

Have fun reading on:

Digitalization in manufacturing?

This is how it works!

It is fundamentally clear that it is difficult to operate entirely without digitalization in today’s industry. Standard processes such as classic Machine Data Acquisition (MDA) or the use of an ERP system are widespread and do their job. And often people know that they need to do something about digitalization, but they don’t tackle it.

“As a result, every wire factory misses out on many possibilities and opportunities to make their own production more efficient, more productive and more transparent,” says IT expert Harald Kimmerle from iT Engineering Manufacturing Solutions GmbH.

Quick and easy implementation

Unlike an ERP, which can often take a long time and be difficult to implement, a smart MES (Manufacturing Execution System) such as the MES Software EMC makes it easy to implement in-house production in just a few weeks and with very little effort.

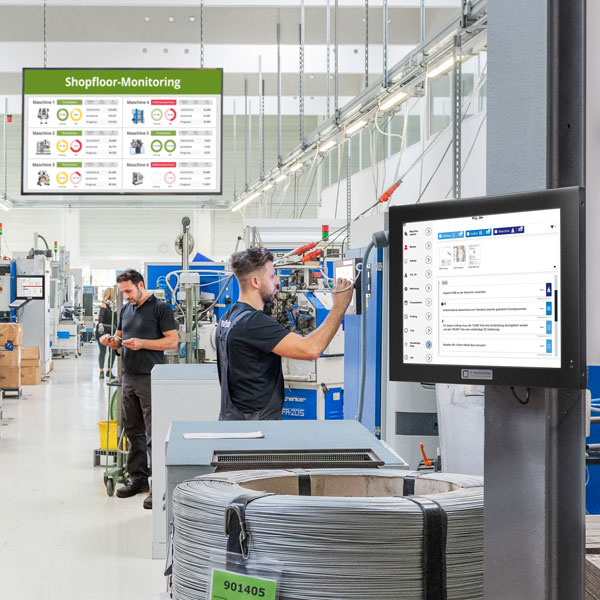

Once all machines and workstations on the shopfloor have been reliably connected, the data streams from the entire production come together in EMC. This creates the basis for a smart factory in which all players involved in production are networked.

ERP and MES go hand in hand

The positive effects of the interaction between ERP and MES quickly become apparent. “The automated dialog and exchange of data and information between ERP and machine control generates reliable information flows for all processes involved in production. All with the aim of enabling efficient production and manufacturing,” says Harald Kimmerle.

Processes on the shopfloor are shortened and optimized. The short-term planning of the MES is continuously supplemented with real-time data from production, which significantly increases transparency and responsiveness, for example in the event of production delays or overproduction.

Use digital opportunities

Access to this real-time information on actual and target values provides decisive added value both on the shopfloor and in management. Directly on the shop floor at the machines, for example, the achievement of the order quantity is digitally recorded and the machine is then automatically stopped if required. The collected “real” data can also be used to analyze production easily and in detail.

This enables smart production controlling, which can be used to quickly identify potential for improvement. For example, the energy values for each order can also be reliably measured and visualized. This provides meaningful values, for example to compare the energy consumption of different machines or to determine order and article-related energy consumption measurements of different work processes.

Simplify and optimize

Many workflows and processes can be simplified with digitalization. “Display article drawings and order information directly at the machine, without paper and order folders. Print out the goods label directly on site when the container is full and simplify container logistics in your production,” explains the IT expert. “Or plan machine utilization with a direct connection to the machine and taking maintenance into account.”

Speaking of maintenance: Thanks to the digital maintenance of the MES Software EMC, maintenance, repairs and servicing can be completely scheduled both manually and cleanly according to individually predefined maintenance cycles. This enables high technical availability and reliable maintenance of machines and systems as well as tools and peripherals.

Experience digitalization live

At wire 2024, the team from iT Engineering Manufacturing Solutions GmbH will be demonstrating how the digital wire factory works with the MES Software EMC and how digitalization is made easy in today’s wire factory. “We pave the way to your successful smart wire factory,” says Harald Kimmerle.