And how does this significantly improve the interaction between production and toolmaking?

In the event of tool damage, it is important to act quickly. The machine is down and every minute counts. This is always a disastrous situation. The worker on the shop floor notices the damage, but now the tool shop must first be informed. By the time repairs begin, a lot of valuable time has been lost during which the machine cannot continue production.

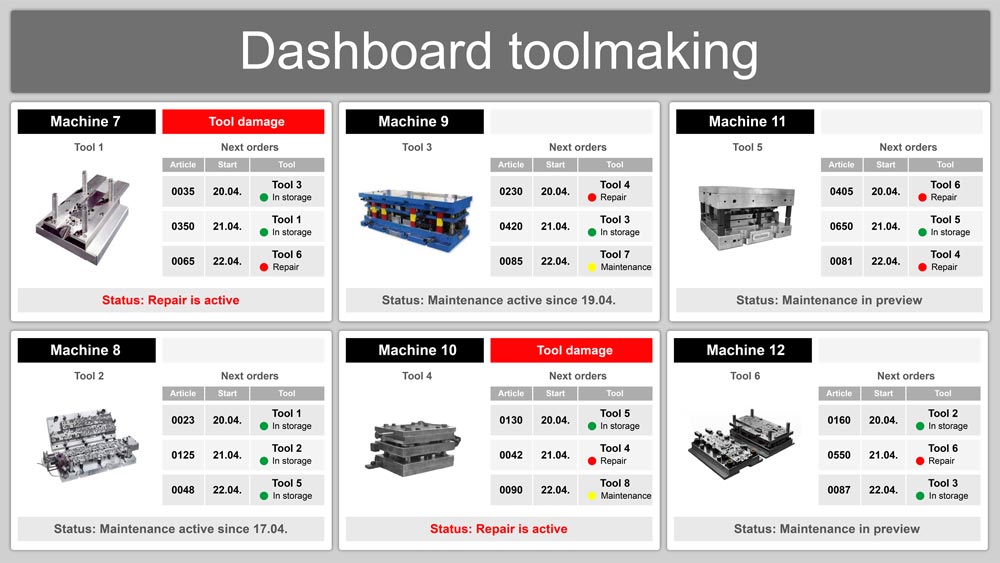

It’s different in the digital factory: if tool damage occurs, it is detected immediately, the information is forwarded directly, and a repair order is created automatically. In addition, the tool shop receives a message via the tool dashboard that the machine is down due to tool damage and can respond immediately. This digital interaction between different departments makes it possible to carry out tool repairs more quickly. This leads to significantly higher machine uptime and thus higher productivity.

The most important benefits of digital tool repair processing in the digital factory are:

- Seamless integration between production and toolmaking

- Faster processing, minimizing downtime and outages

- Transparency and traceability through complete digital documentation of all repairs, including descriptions and photos

- Reduction of cost-intensive emergency repairs

- Well-founded analyses of wear, sources of error, and costs

- Derivation of maintenance with maintenance cycles

Faster repair processes

Digital processing means repairs can be started faster and carried out more efficiently. In the event of malfunctions or detected wear, the system automatically generates a repair order. Employees can then start the repair directly via the MES Software EMC or by scanning a QR code on the tool. This eliminates waiting times.

Complete documentation of tool repairs

The EMC Maintenance module allows all repairs and repair steps to be clearly documented. The worker can describe the fault directly in the respective repair order. In addition, photos can be easily taken before, during, and after the repair using the MES tablet, which are also stored digitally in the repair order. Clear documentation of tool repairs helps to draw valuable conclusions about wear and tear and sources of faults.

Transparent tool status in real time

The current status of each tool can be viewed digitally at any time. This means that employees and managers always know which tools are ready for use and which are undergoing repair.

The status of all tools is automatically displayed in the tool dashboard. Thanks to the live connection to the shop floor, data is transferred directly. Toolmaking employees can immediately see if a tool has been damaged somewhere in ongoing production or if tool maintenance is due.

The continuous availability of tool data makes it possible to respond quickly to malfunctions and get the machines up and running again in no time. This also improves the interaction between production and toolmaking. Employees on the shop floor do not have to leave their workstations to inform the toolmaking department.

Digitally controlled, documented, and evaluated

Every repair, including all necessary replacement parts, is digitally recorded and documented in the life cycle card, along with the time, person responsible, and materials used. This creates complete transparency regarding all work performed on the tool. All repair data is available for evaluations, trend analyses, and preventive measures.

Easily derive future maintenance tasks with maintenance cycles

Future maintenance schedules can be derived from the evaluation of repairs. This means that tools are not only repaired when damage occurs, but are also maintained at an early stage based on the findings from the repair analysis. This prevents consequential damage and thus extends the service life of the tools.

Conclusion

The digitization of tool repairs is a key lever for significantly reducing machine downtime, avoiding production losses, and sustainably increasing productivity.

Damage is immediately detected, digitally reported, and automatically forwarded to the tool shop, saving precious minutes in which the machine can resume production. Complete documentation of repairs, including detailed descriptions and photos, as well as transparent tool data in real time, ensure that repairs are carried out efficiently, to a high standard, and without any loss of information.

The interaction between production and toolmaking becomes seamless, making manufacturing more stable and flexible. Companies that digitize their tooling processes are taking an important step toward a lean, digital factory. And thus a clear competitive advantage in their day-to-day business.

Contact us

Do you have further questions about the digital integration of tool repairs with our MES Software EMC or about implementing your digital factory?

We will be happy to advise you and provide you with a personalized offer.

Simply call us on +49 7127 – 9231 10 or send us an e-mail to info@ite-ms.de

Frequently Asked Questions (FAQ)

How do digital processes support tool repairs?

Digital processes allow for immediate detection and notification of tool damage. Repair orders are automatically created and the toolmaking department is informed right away, reducing reaction times and minimizing downtime.

What are the benefits of digital documentation for tool repairs?

Digital documentation ensures complete traceability. All repair steps, error descriptions, and photos are digitally recorded, providing transparency and enabling analysis of root causes and maintenance cycles.

How does digitalization improve the collaboration between production and toolmaking?

Digital dashboards and automated communication ensure that the toolmaking department is immediately informed of tool defects. This seamless collaboration reduces machine downtime and streamlines workflows.

What is the tool dashboard and what are its benefits?

The tool dashboard displays the real-time status of all tools. Employees can instantly see which tools are available, under maintenance, or damaged—enabling quick reactions and higher machine availability.

How do digital repair data support preventive maintenance?

By analyzing digitally documented repairs, companies can derive maintenance cycles. Tools are serviced proactively, preventing damage and extending tool life.