WAFIOS In-house Exhibition:

Innovation Days 2025

Smart Wire Factory:

How to make your production digital – step by step or holistically

The WAFIOS In-house Exhibition “Innovation Days 2025” will take place in Reutlingen from May 7 to 9, 2025. We are delighted to be back at this international event for the wire and tube industry as a long-standing partner.

On site, we will show you how the Smart Wire Factory works in the digital wire factory and how our smart MES Software EMC digitalizes, simplifies and smartly connects various processes. It supports you in sustainably increasing productivity and offers flexible planning of machine utilization. It also enables you to achieve virtually paperless production through the use and development of innovative modules: From the acquisition and visualization of machine data, to the planning and provision of important information and documents, to the printout of the goods label and beyond.

Well-known companies from the wire and forming industry have been relying on our MES Software EMC and our industry experience for 30 years. We know exactly what makes companies tick and how we can successfully implement the digitalization of your production easily and without great effort.

Our Innovation Days 2025 highlight:

Completely digital, intelligently networked and paperless production

From the acquisition and visualization of machine data, through order planning and the provision of information and documents, to automated production controls and the printout of the goods label for maximum efficiency, transparency and productivity.

Reliable acquisition and visualization:

central key production figures for everyone, everywhere

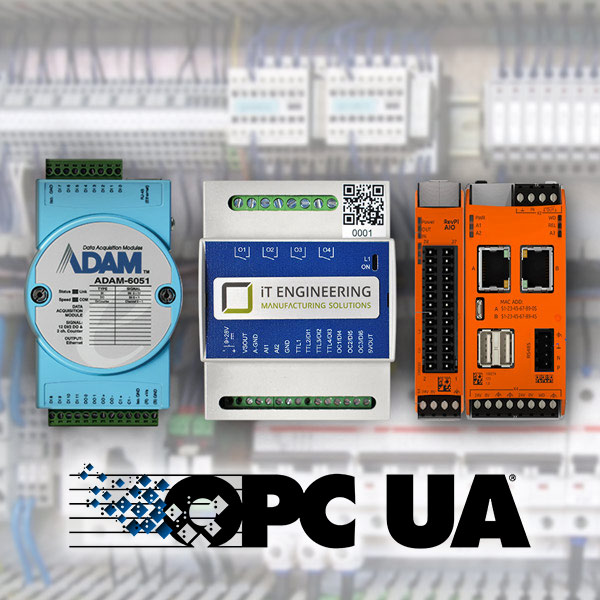

Data from all machines, no matter how old, is acquired reliably and automatically in real time. In addition to the status of the machines, information on faults, necessary operator interventions and the status of maintenance are also recorded. Record the status of production orders, automatically in combination with the MDA or by input from your employees directly at the terminal on the store floor.

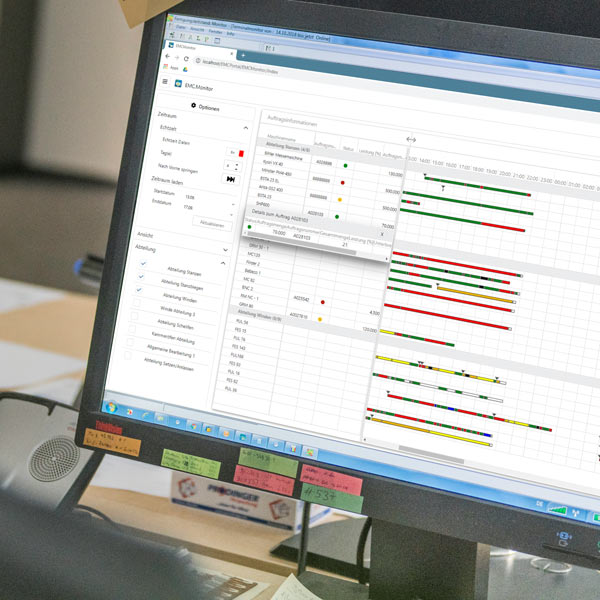

Based on the recorded data, digital shopfloor monitoring always provides information on the current status of production. Whether on the production monitor, PC or mobile device. The recorded and bundled production data is visualized in real time for the target group. Dashboards on large-screen monitors directly on the store floor make machine downtimes, reduced speed, quality losses and system malfunctions immediately recognizable.

Flexible planning of machine utilization with navigation functionality

The roughly planned orders are received by the ERP and supplemented and adjusted in short-term planning with the data collected in real time on the store floor (machine occupancy, tool allocation, employees or downtime reasons). The work processes for the orders are then planned for the individual resources (machines, workstations).

The Navi function automatically adapts your planning to the current order progress of the machine and visualizes the planned order sequence digitally on the machines.

Bye Bye order folder:

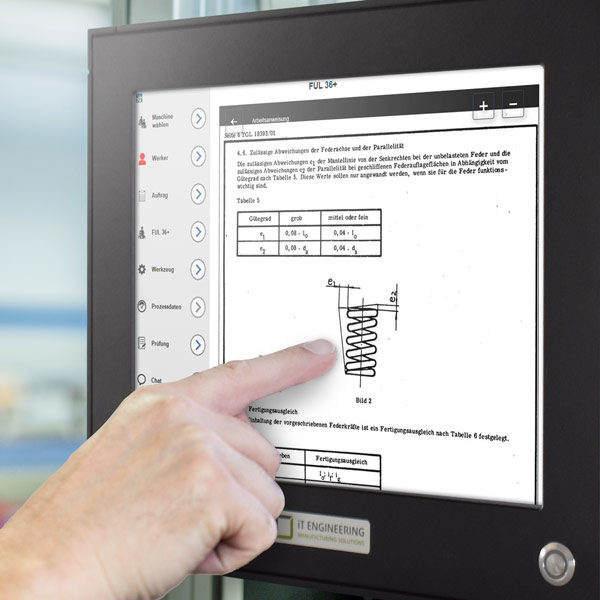

Paperless production thanks to the provision of all important information and documents directly at the terminal

In the digital factory, all documents and information relevant to the order are available digitally and can be called up at the touch of a button directly at the MES terminal in production or on a mobile tablet.

In addition, employees add their experience and information directly on site. This means that the collected knowledge is available anytime and anywhere. This saves every employee a lot of time that would otherwise be spent searching for, finding or printing out the necessary files, drawings or instructions. It also enables virtually paperless production. Without separate printouts or physical order folders.

Simple, production-accompanying control: reliably carry out and document production tests

The collection of data from all machines, no matter how old, makes it possible to continuously monitor current production.

When a predefined event is reached, such as an inspection interval being exceeded or a fault being triggered, a message is automatically displayed on the machine terminal, prompting the operator to carry out production checks or inspections. Similar to a checklist, the processes are supplemented by clearly scheduled and digitally documented checks.

This significantly increases the quality of production.

Print out the goods label directly at the machine and easily retrieve information at any time via QR code and track containers, batches and products cleanly

In digital production, there is no longer any need to print out and manually fill out goods labels. Simply print out the goods label directly at the machine, manually or automatically by the machine or a container changer. All quantities are reliably transferred from the machine data acquisition system. This is not only simpler, more convenient and time-saving, but above all less prone to errors.

It also enables seamless traceability of products, batches and processes as well as predictive quality control and quality assurance in production. All information from planning and production to storage can be accessed digitally at any time and in a bundled format.

The Smart Wire Factory can do even more

The innovative MES Software EMC from iT Engineering Manufacturing Solutions GmbH has many other options for cleverly digitalizing your wire factory and thus optimizing numerous processes in your production.

We look forward to seeing you

Benefit from our extensive specialist knowledge and many years of expertise in the field of smart networked production. We look forward to welcoming you to our stand at the WAFIOS In-house Exhibition “Innovation Days 2025” and to exciting discussions about the many possibilities of the Smart Wire Factory.

Further information about the WAFIOS Innovation Days 2025 (registration, exhibition program, presentations) can be found here: