Digital detailed planning of production

Precise planning of machine occupancy

with navigation function

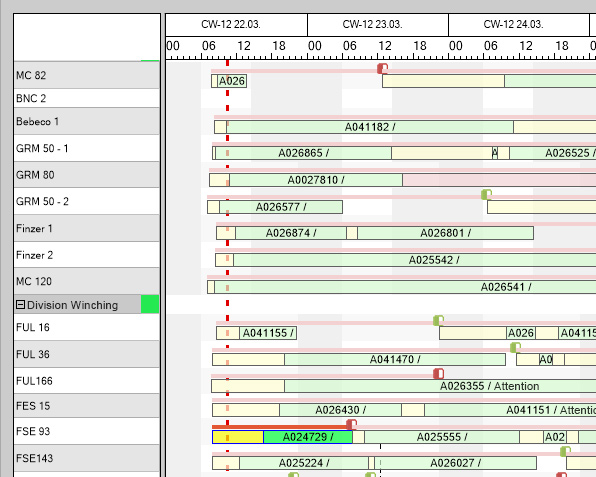

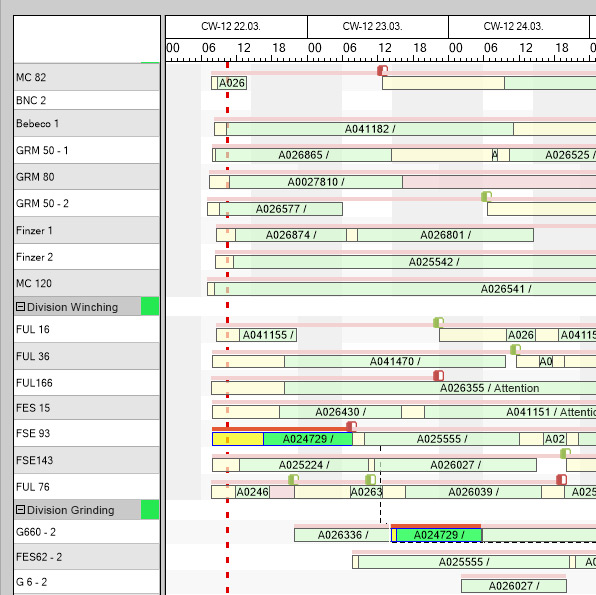

Precise planning of machine occupancy with navigation function

Create realistic detailed planning of production for machine assignment with the EMC Detailed Planning module. The roughly planned orders are received by the ERP and supplemented and adjusted in the short-term planning with the data collected in real time on the shopfloor (machine occupancy, tool allocation, employees or reasons for downtime). As a result, the operations of the orders are planned on the individual resources (machines, workstations).

The navigation function automatically adjusts your planning to the current order progress of the machine and visualizes the planned order sequence digitally on the machines.

Perfect overview

of the machine assignment

in the Gantt chart

Simply plan the machine assignment and distribute it by drag & drop. Or roughly planned from the ERP system and adapted to the machine capacities.

The current and clearly arranged information enables short-term rescheduling. Unpredictable production delays can be localized at any time. Add incoming orders at short notice simply by drag & drop.

In addition, you have the option to plan orders specifically according to priority and urgency by displaying feasible delivery dates. Detailed planning informs you at an early stage if an order is postponed and how this change affects the delivery date.

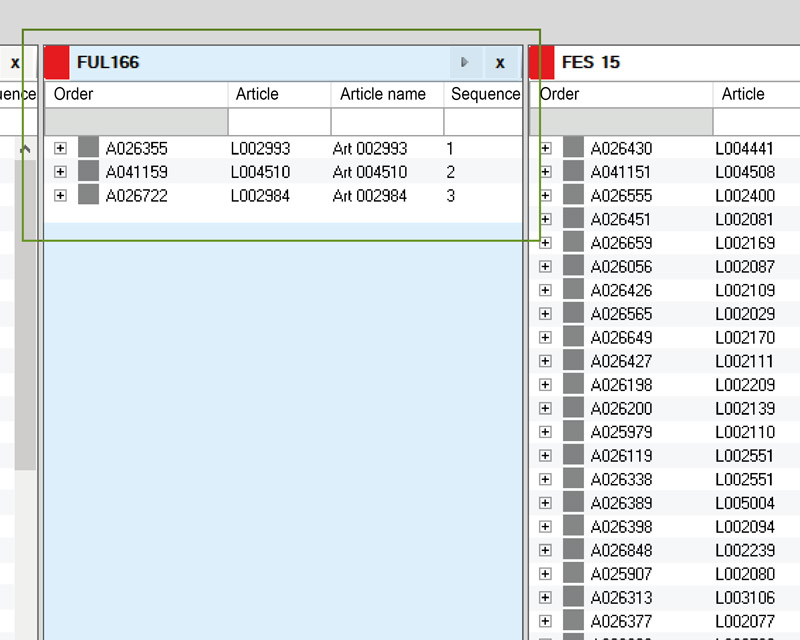

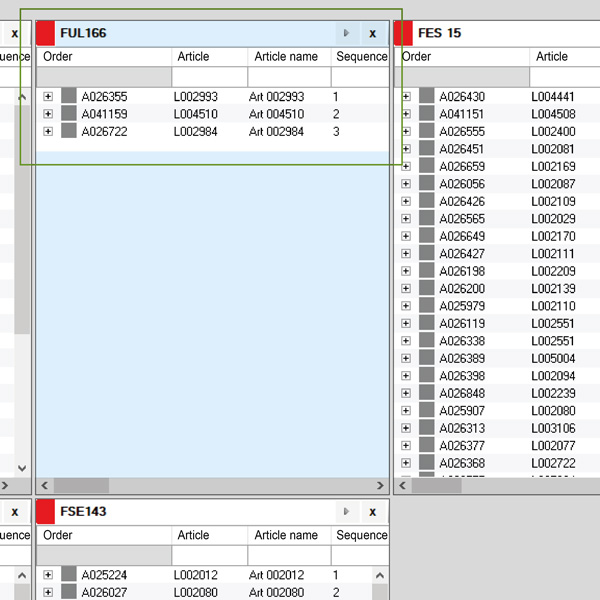

Gantt chart or list view

Depending on your preference, select the list view or the graphical Gantt chart display for digital planning. In the list view, moving an order is very quick. It is particularly suitable for a large number of machines and thus enables simple rescheduling in the plan list by moving the operation.

The detailed planning of production in the digital factory

Planning in the digital production of the future eliminates the need for printed production lists and their distribution on the shop floor. This means that the current plan sequence is displayed directly on the MES terminal and in the shopfloor dashboard. In addition, the order is registered directly via the displayed plan list.

Comprehensive clarity about the order situation

and production capacity utilization with EMC Detailed Planning.

iT Engineering Manufacturing Solutions GmbH

Reach your destination smarter with navigation function

The actual progress is continuously reported back to planning after the start of the order at the machine – i.e. in real time. Planning then updates itself automatically, performs a forecast calculation for the end of the order and updates the start date of the following orders.

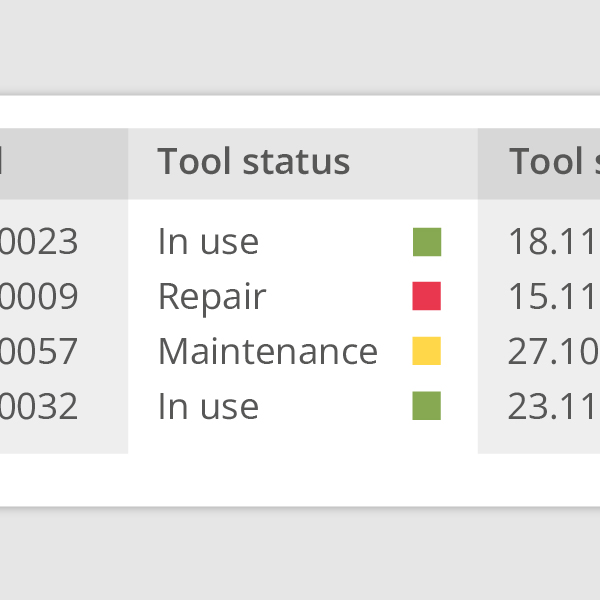

Produce and plan more efficiently with maintenance integration

The digital information exchange and access of the MES Software EMC enables a predictive control of the individual production processes via the most important departments. For example, in the event of a repair, the tool shop is informed directly from the machine terminal. In addition, this information also reaches production planning directly without detours.

This means that the planner knows the current tool status at all times. Upcoming maintenance and current repairs are automatically integrated into detailed planning. This ensures realistic and smooth production processes. In addition, the mold shop receives the information from the planning which tool is needed when and which maintenance is due.

All modules: