Efficient operating data acquisition

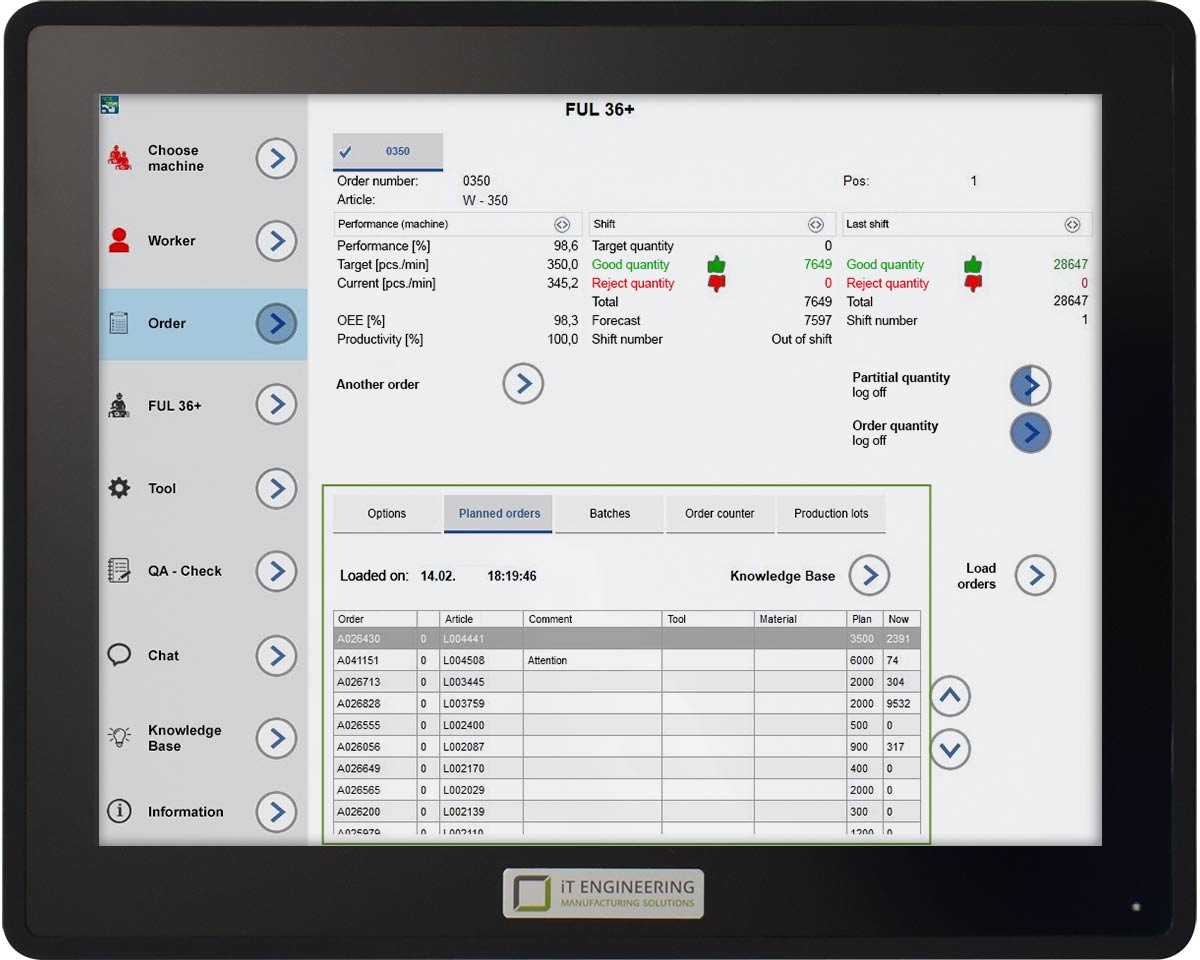

Complete order information in real time:

Seamless and digital, transparent and paperless

Use the EMC Operational Data Acquisition basic module to automatically record the status of production orders, automatically in combination with EMC Machine Data Acquisition (MDA) or through entries made by your employees directly at the terminal on the shopfloor. At the same time, you monitor your orders and the individual operations.

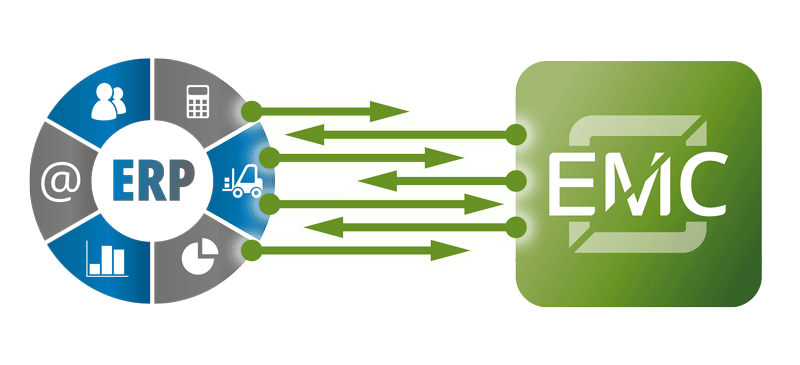

All relevant order-, article- and person-related data is thus recorded seamlessly in real time with the operational data acquisition and reported back to the ERP system. In addition, operating data can also be reliably recorded, for example during assembly or at manual workstations, completely without machine data.

Connectivity to the digital workplace in manufacturing

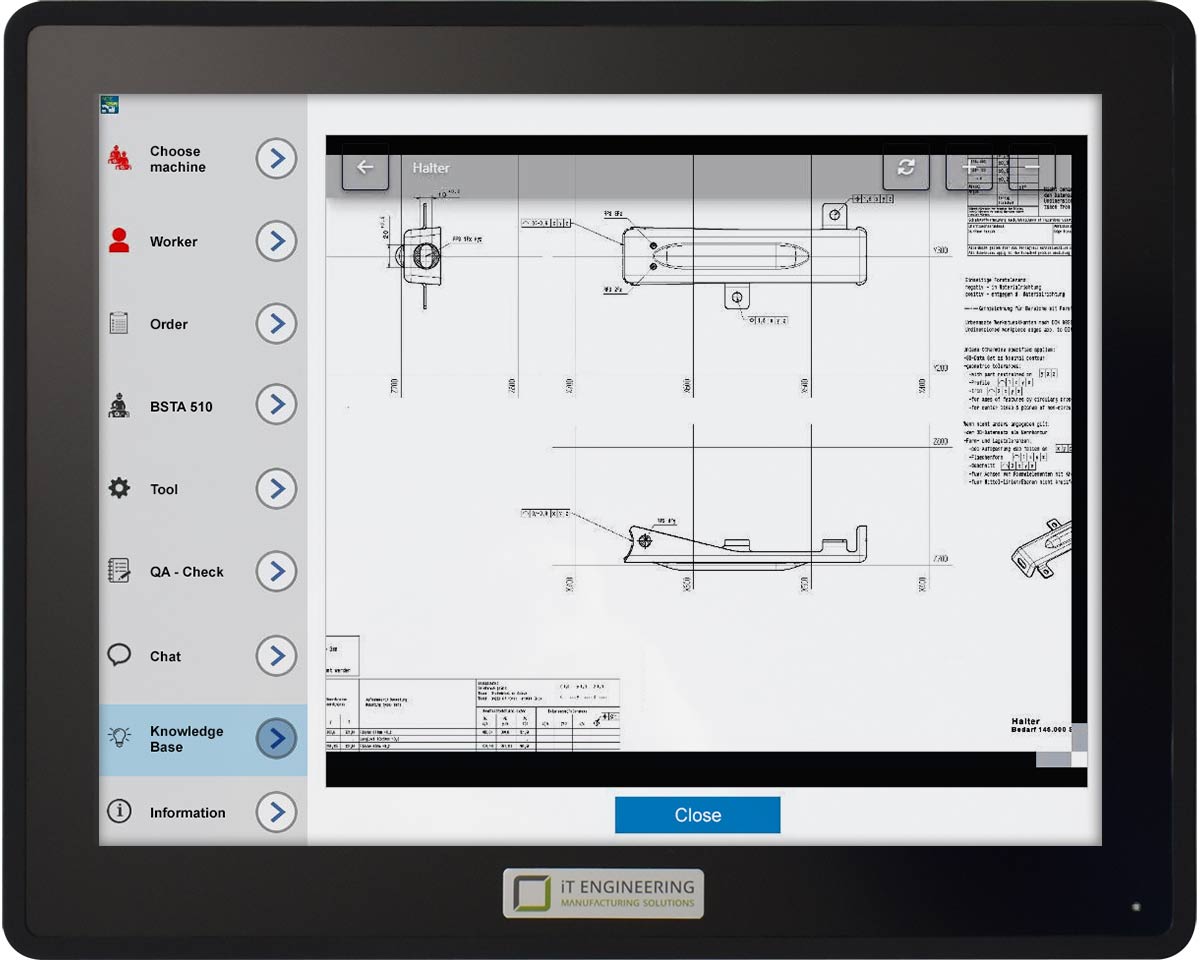

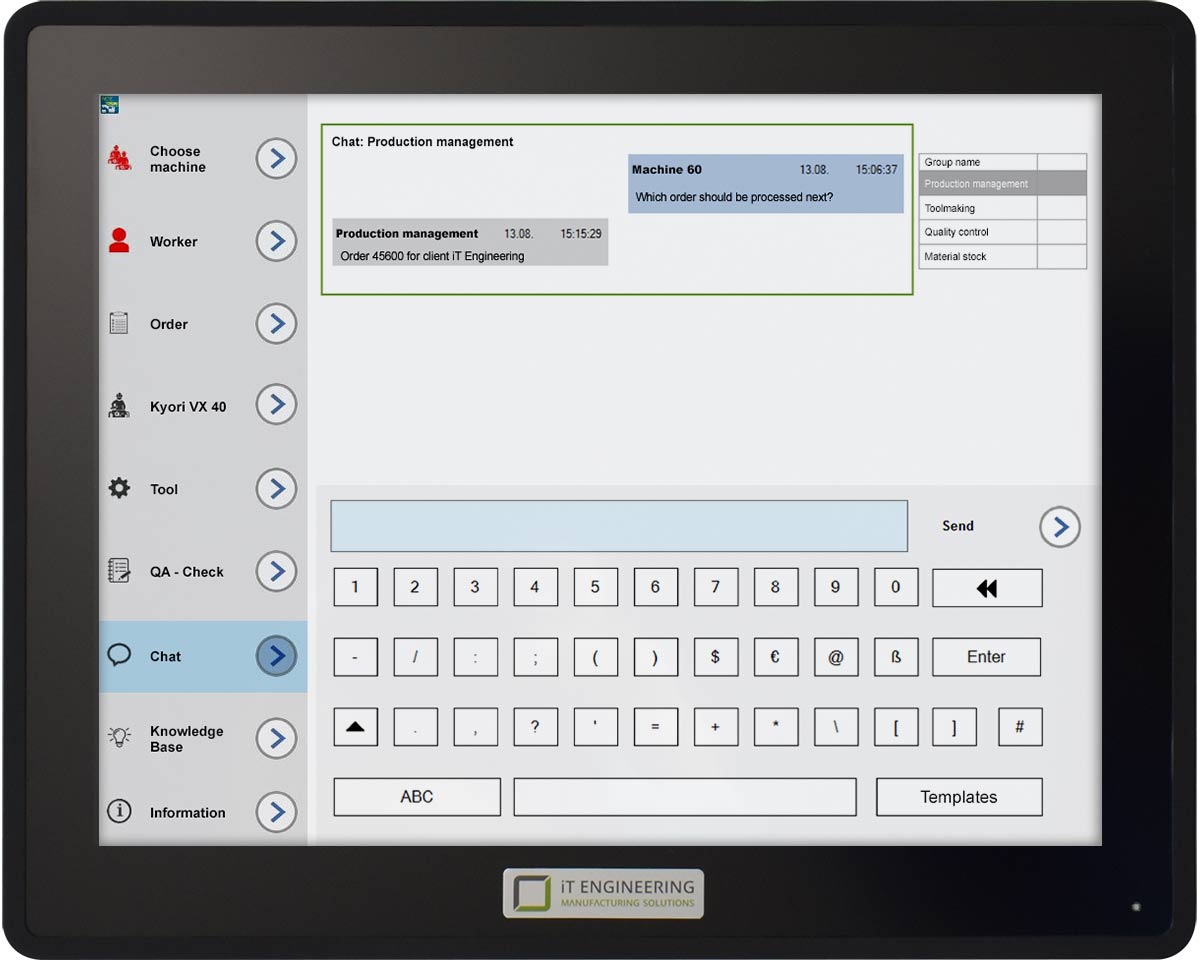

Away from the pure message terminal and towards the provision of information. The MES terminals on the shopfloor make it easier for workers to work. They provide information about current and planned orders and are easy to operate thanks to a self-explanatory user interface with touch screen function. This makes it easy to record operating data on the fly.

Less effort and fewer errors thanks to paperless production. This includes drawings, assembly instructions, videos and much more. Workers are relieved of handwriting and have a record of their work.

Efficient operational data acquisition means transparency in manufacturing. Knowing the status of the job – in real time – is the key success factor.

iT Engineering Manufacturing Solutions GmbH

Acquire operational data

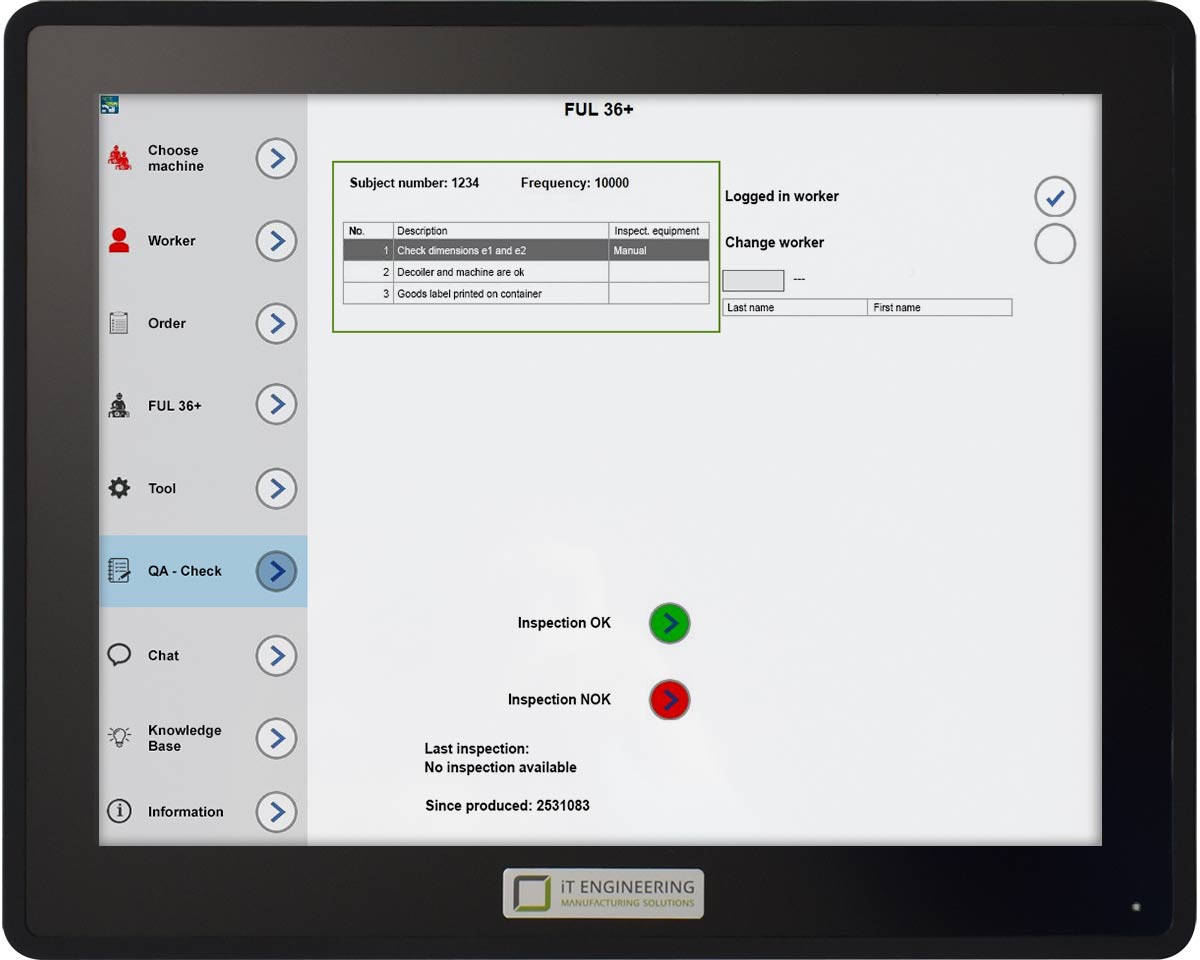

Map your production processes with the MES Software EMC and record all data and production processes that cannot be recorded by the machine directly at the machine via manual recording:

Order number, batches, organizational downtimes, rework, scrap, person-related times, and much more.

Reliable data exchange with the ERP

The MES data in the ERP system saves manual feedback in the ERP. They support material logistics and post-calculation.

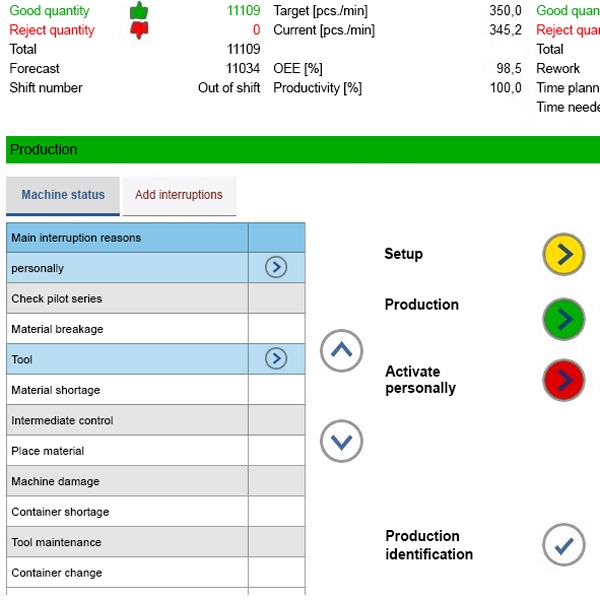

The recorded actual data from production is reported directly back to the ERP. In real time, the MES Software EMC from iT Engineering Manufacturing Solutions GmbH displays all important order-related information in detail, such as the current status of orders and operations, interruptions and order progress, comparison of target and actual values, or even the order backlog and order sequence.

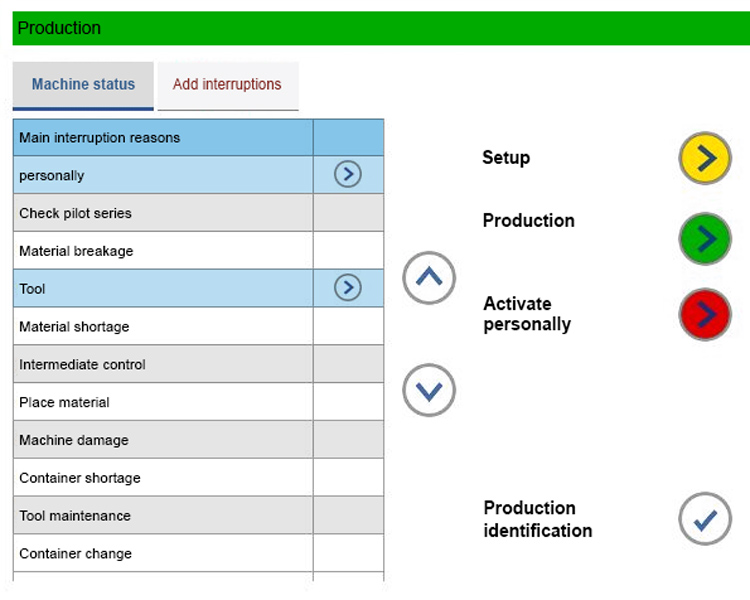

Intuitive operation for efficient operational data acquisition

The self-explanatory interface of the MES terminals makes operation intuitive – for your employees on the shopfloor.

Entering reasons for downtime, material batches or information are just one example and are an important building block for transparent and seamless operational data acquisition.

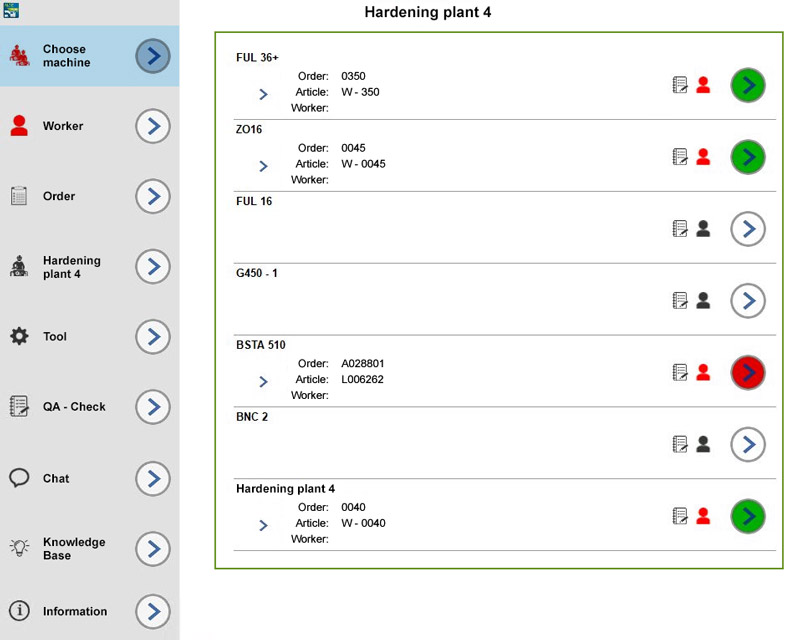

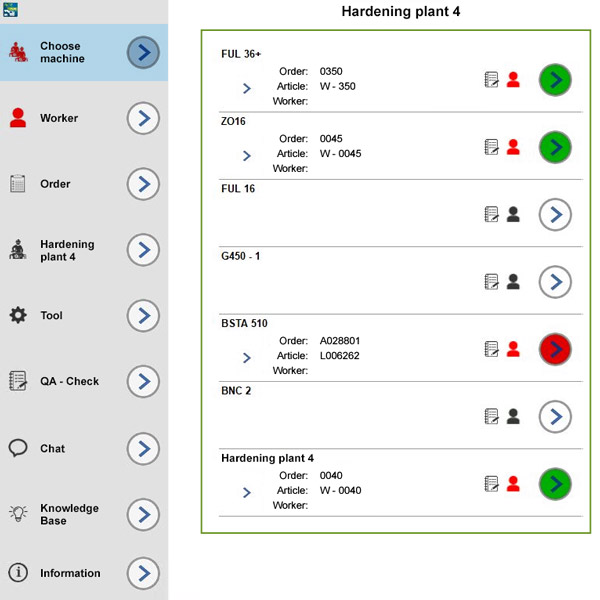

Group terminal or manual workstation

Whether multi-machine operation or single workstation:

Our MES system and EMC Operational Data Acquisition are configured according to your production and process flows to perfectly reflect the nature of your manufacturing.

All modules: