Intelligent Order Management:

Manage all production orders transparently

Efficient control of machine and department capacity utilization

With EMC Order Management of the MES Software EMC, you can easily manage all orders in real time, monitor them transparently and, if necessary, simply reschedule them to avoid overcapacity. EMC Order Management offers you the important flexibility during ongoing production to react quickly to disruptions, for example, and then simply make changes.

The orders roughly planned by the ERP with infinite capacity are reliably adopted and can be easily adjusted by quickly shifting orders. Unlike separately managed lists, digital networking gives you the security and advantage that the worker is always reliably shown the correct order sequence at the terminal. The result is better utilization of machines and departments and less idle time.

Digital order management brings with it numerous advantages that improve both the efficiency of production and the quality and transparency of processes. Here is an overview of the most important benefits:

- Better transparency and traceability thanks to the continuous monitoring of production in real time and the complete documentation and traceability of every order

- Increased efficiency and through better planning, rapid response to overcapacity or disruptions and optimized utilization of machines and departments

- Reduction of errors thanks to automated order data: Digital transmission eliminates transmission errors, e.g. from handwritten routing slips.

- More flexible production: changes can be incorporated directly into production without any detours.

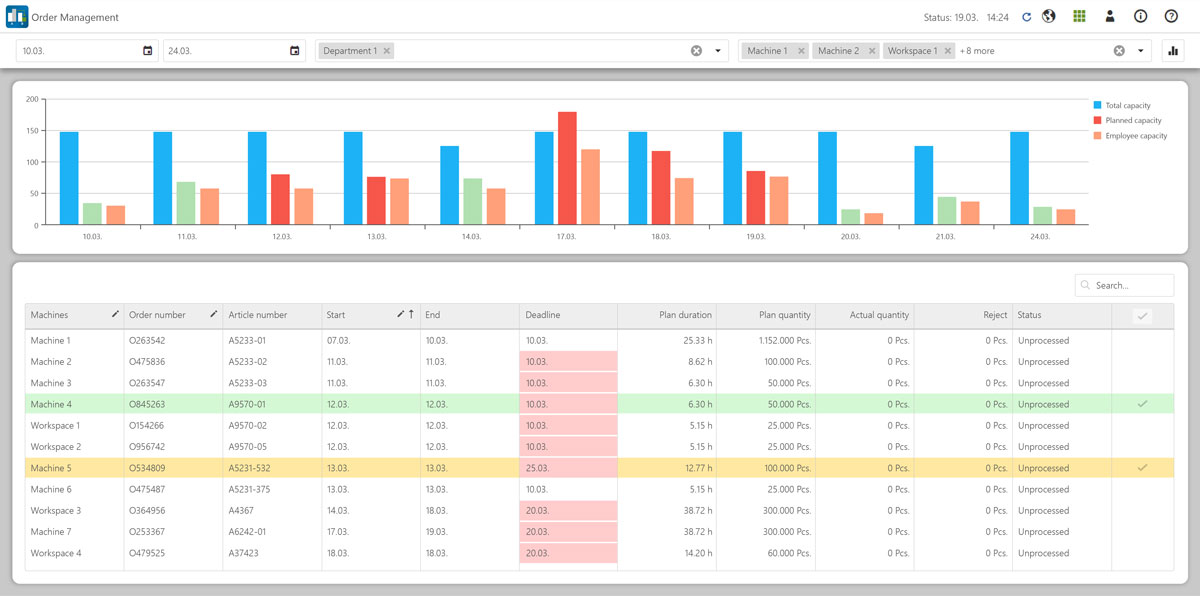

Perfect overview of machine and department utilization

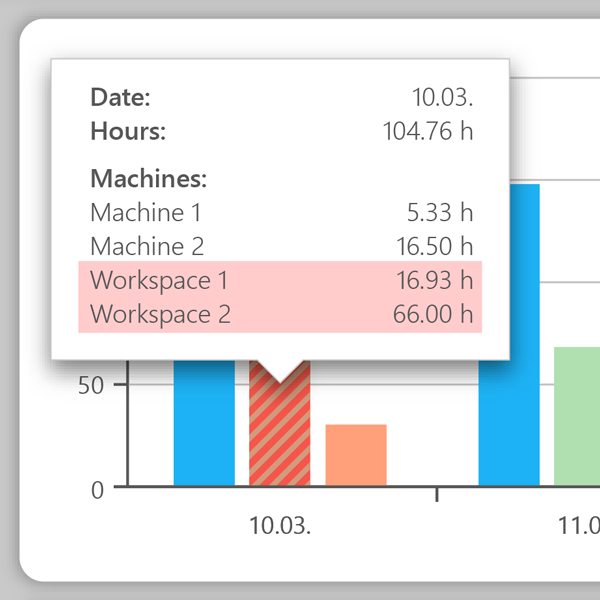

In the EMC Order Management module, the machine and employee capacities of the department and the list of production orders per machine are displayed in real time based on the selected filters. Thanks to real-time monitoring, you always have a complete overview of machine and department utilization and can intervene directly if necessary.

New or changed orders are called up directly from the ERP and displayed in color. The foreman can then control and plan the orders in such a way that overcapacity is avoided.

Department capacity utilization always in view

The blue bar always shows the possible machine working time of the selected department. The second bar shows the planned capacity and utilization of the department in detail. Overloaded machines or workstations are automatically highlighted in color.

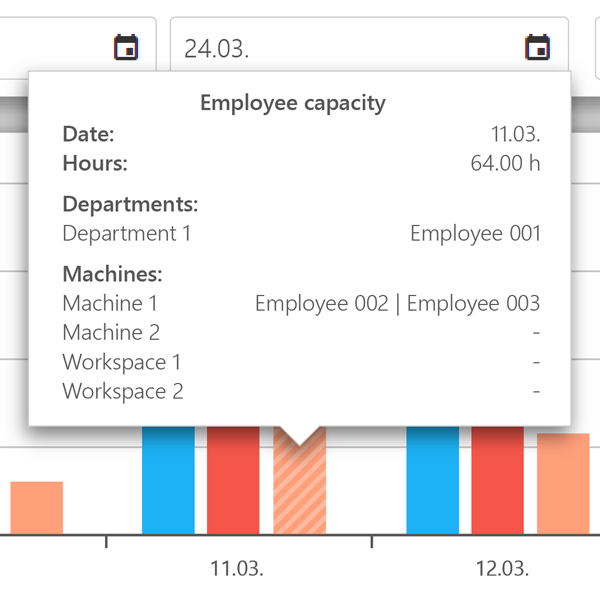

Manage employee capacities within Order Management

Which employees are scheduled for the machines or the department? In combination with the EMC Team Planner module, the employee capacities are displayed via a third bar. This allows the foreman to see immediately if he needs to schedule more people for the orders.

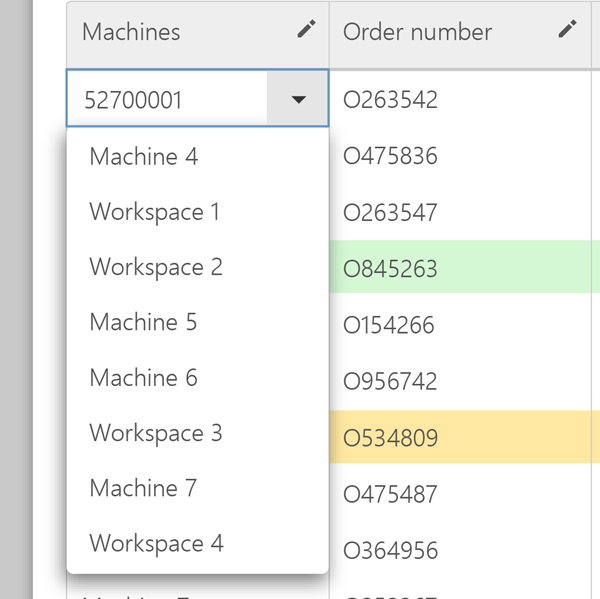

Assign orders to a new machine

The digital order management system offers several options for moving orders if required.

The order can be easily moved to a new machine using the machine name. To do this, simply select the new machine and move the order.

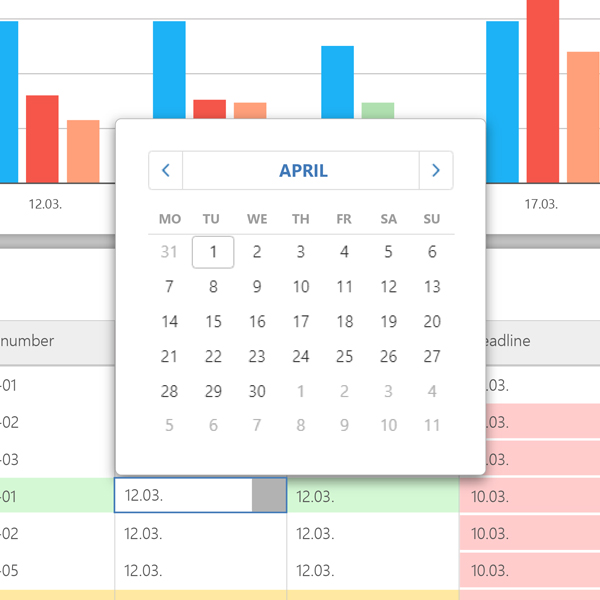

Simply move the start date of orders

In addition to assigning an order to a new machine, orders can also be rescheduled. If there are capacity bottlenecks, the start date of the orders can be postponed via the calendar.

Regardless of which type of order postponement the foreman chooses, thanks to digital networking, the worker is always shown the correct planning sequence of the orders on the machine terminal.

All modules: