15th Metal Stamping Congress 2025 in Dortmund

Produce more intelligently and efficiently with the digital stamping factory

The 15th Metal Stamping Congress 2025 will take place in Dortmund on April 7 and 8, 2025. We will be there again as an exhibitor and will show participants everything to do with the digital upkeep of machines and the maintenance of tools with the MES Software EMC.

We will also show how the smart networked information flow works in the digital stamping factory, how you can simplify and optimize your processes and thus significantly increase the efficiency of your production. The MES Software EMC from iT Engineering Manufacturing Solutions GmbH makes your stamping factory digital and fit for the future.

Digitalization boosts efficiency, productivity and sustainability

With 30 years of experience and expertise, we know the market and the needs of the stamping technology industry inside out. Based on this, we have been pursuing a consistent product strategy for decades, enabling us to adapt our MES Software EMC optimally to all challenges and individually to your production.

We enable smart manufacturing

Our highlight for the Metal Stamping Congress 2025:

The digital maintenance and servicing process for tools, machines and spare parts

No paperwork. Clean documentation. Higher productivity.

This is how maintenance and servicing works today.

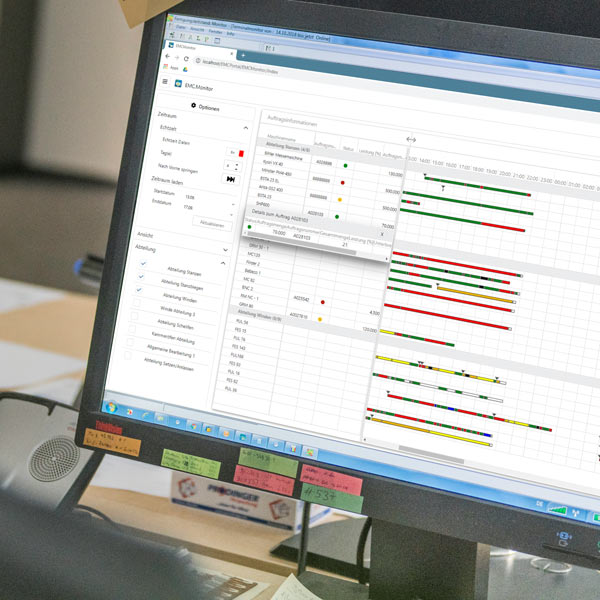

With our MES Software EMC, you have maintenance and servicing for machines and tools under control at all times. With the EMC Maintenance module, you can easily manage your tools, machines and spare parts, their maintenance and use. Completely digital and clearly traceable.

Optimal maintenance strategies with digital maintenance

Necessary maintenance measures are carried out in the digital factory at the best possible time. The MES Software EMC ensures transparency in the use of tools, machines, spare parts and test equipment through consistent process monitoring of maintenance, repairs and servicing.

The optimum time for maintenance and servicing measures is determined seamlessly and all measures are documented.

The digital lifecycle card creates clarity

As in a maintenance log, all tool and machine maintenance and repairs carried out are documented in the digital lifecycle card of the MES Software EMC. The current status, availability and history of the machines and tools are also stored in the digital lifecycle card.

Start and carry out maintenance easily and document it cleanly

Start tool maintenance or machine maintenance either manually via the portal of the MES Software EMC or by scanning a QR code attached to the machine or tool. In this way, all maintenance steps carried out can be fully documented in the digital life cycle card.

This provides important information at any time, such as which tool inserts are responsible for production downtimes. This allows the maintenance department to access a wealth of data for optimization purposes, helping to increase productivity and effectively avoid machine downtime due to unplanned maintenance.

The digital factory can do even more

Our innovative MES Software EMC has many other options for cleverly digitalizing your stamping factory and thus optimizing numerous processes in your production.