Digital maintenance

for machines and tools

Complete digital documentation of maintenance, servicing, and repairs

One of the biggest challenges in manufacturing is keeping machines running and avoiding production delays. The precise, comprehensive definition and documentation of maintenance, servicing, and repairs for machines and tools of varying complexity—with or without interchangeable modules, inserts, etc. – as well as peripherals, is a prerequisite for high plant effectiveness.

In many companies, maintenance and repairs are still recorded by hand or in Excel spreadsheets. This leads to information gaps, a lack of traceability, and unclear responsibilities.

From analog to digital – why the changeover is worthwhile

With the EMC Maintenance module, you can control, document, and analyze maintenance, repairs, and servicing, including all components used, such as interchangeable modules, conversion kits, and spare parts, completely digitally, both for machines and tools as well as peripherals. All maintenance and repair activities can be planned automatically, carried out systematically, and documented centrally. This ensures high technical availability of your production equipment, avoids downtime, and creates maximum transparency about the condition of your resources.

Plan, perform, and document machine maintenance and tool servicing easily and reliably

The EMC Maintenance module of the MES Software EMC maps the entire maintenance process digitally, transparently, and in a standardized manner: from planning to tracking. This not only makes every maintenance and repair task easier, but also more traceable and efficient.

The consistent digitization of tool maintenance and machine servicing results in clear, repeatable processes and a uniform level of information for all parties involved. EMC Maintenance combines practical functions with intuitive operation, thus creating the basis for modern, networked maintenance organization and documentation.

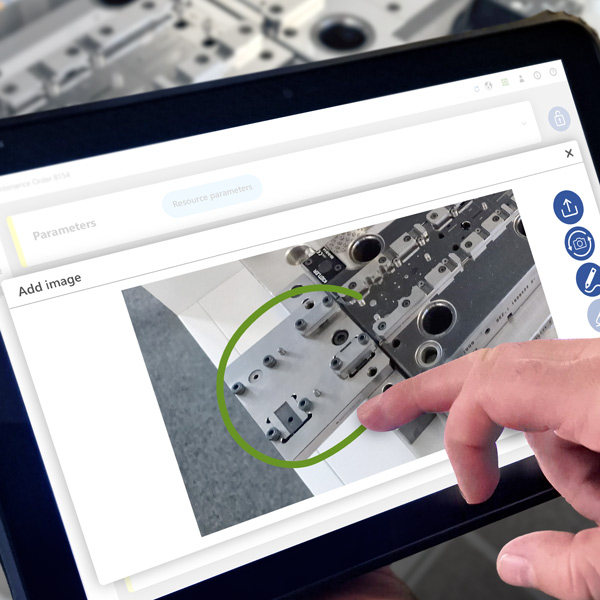

The module can be used both on a tablet and on a desktop. This means that all maintenance information and life cycle data is available anytime, anywhere – directly at the machine, in the tool shop, or in the office. Intuitive operation ensures that maintenance is carried out quickly, safely, and in a standardized manner.

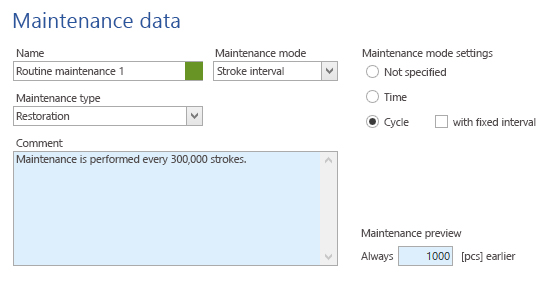

Define maintenance and cycles

All maintenance tasks can be stored centrally as master data and clearly structured. Maintenance cycles can be defined based on individual criteria such as production volume, cycles, operating hours, or service life.

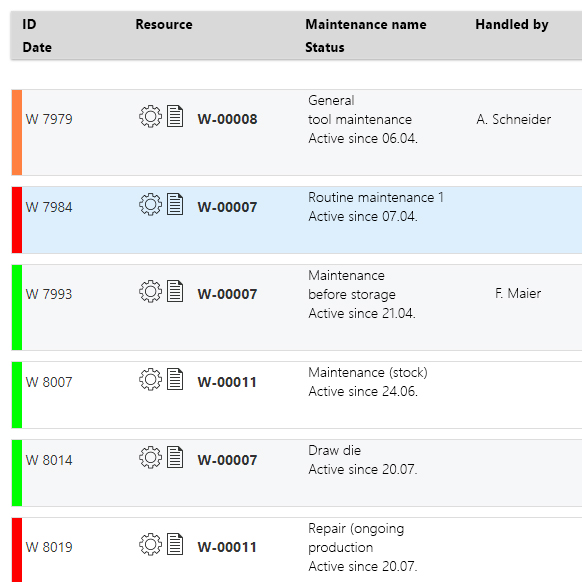

The integrated maintenance manager automatically monitors when maintenance, servicing, or inspection is due. It generates a maintenance order in good time when the maintenance cycle is reached. The upcoming maintenance order is displayed in the machine or tool construction department in accordance with the defined maintenance preview. This means that no maintenance is overlooked and servicing can be planned in advance.

Start maintenance and servicing

– directly and intuitively

Upcoming maintenance or servicing can be started very easily by scanning the QR code on the machine or tool.

The corresponding maintenance order opens automatically on the MES tablet and displays all the necessary information: from work instructions and important documents to the spare parts list, checklists, videos, and images.

This allows the employee to start maintenance immediately without having to search for documents or instructions.

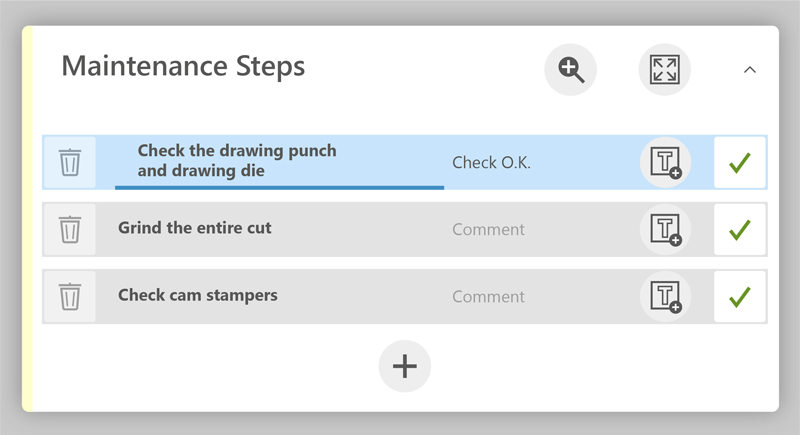

Digital maintenance with checklists and step-by-step instructions

Maintenance is carried out in accordance with the specified maintenance steps. Depending on your preference, you can check off the completed maintenance steps using either the simplified or detailed checklist entry. This ensures that maintenance is always carried out completely and according to the same quality standards, regardless of who performs it. Complex maintenance tasks thus become understandable, transparent, and reproducible.

Knowledge transfer through maintenance videos

Digital maintenance is interactive: videos can be integrated directly into the maintenance process for support. They visually demonstrate how certain tasks or checks are to be carried out and ensure that all employees have the same level of knowledge. This is a major advantage, particularly in the case of infrequent maintenance or complex tools, as it helps to avoid errors and ensure quality.

With the kind support of hapema GmbH

Clear documentation of maintenance

with pictures and comments

During maintenance, servicing, or repair, photos can be taken, tagged, and directly assigned to the respective activity. For example, a worn part, a crack, or a special feature can be documented immediately and easily. Additional comments and comment templates allow observations or suggestions for improvement to be recorded. All data is automatically saved and flows into the digital life cycle card of the machine or tool.

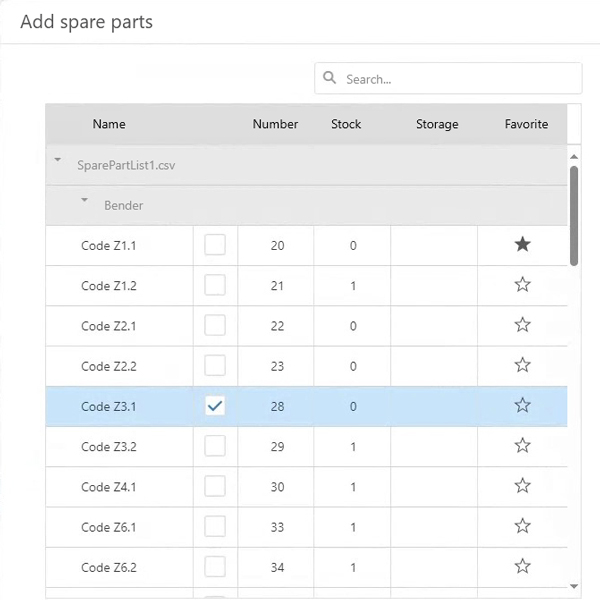

Simply add spare parts for maintenance

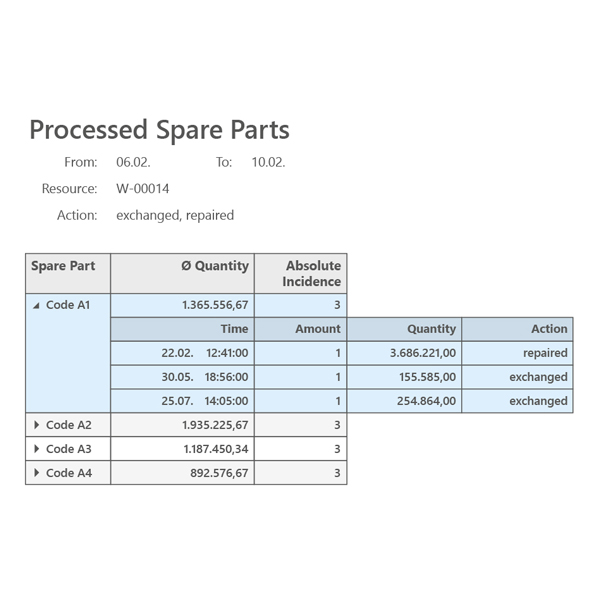

In combination with the EMC Spare Parts Management add-on module, your spare parts, whether purchased or manufactured in-house, are neatly stored and listed at all times.

Simply select the required spare part from the list during maintenance and add it to your maintenance task. Thanks to automatic inventory monitoring, you can always see exactly which spare parts are available.

Complete traceability:

The digital resume card provides clarity

All maintenance, servicing, and repair work carried out is documented in full in the digital life cycle card, providing information on the current status and availability of the resource. This means that the entire lifetime of the machine or tool is documented in the history. Further information such as articles and orders are linked. Built-in spare parts and their quantities can be traced precisely.

The digital life cycle card can be accessed from any location: at the machine in the event of a repair, in the tool shop during maintenance, or in quality assurance during root cause analysis in the event of unmet quality requirements.

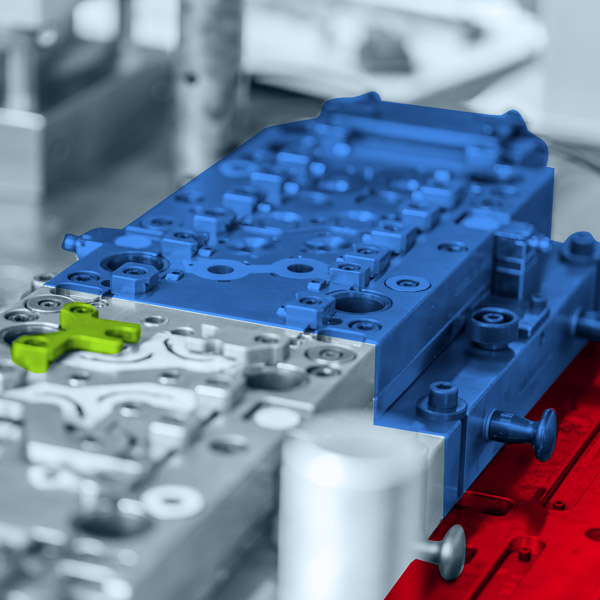

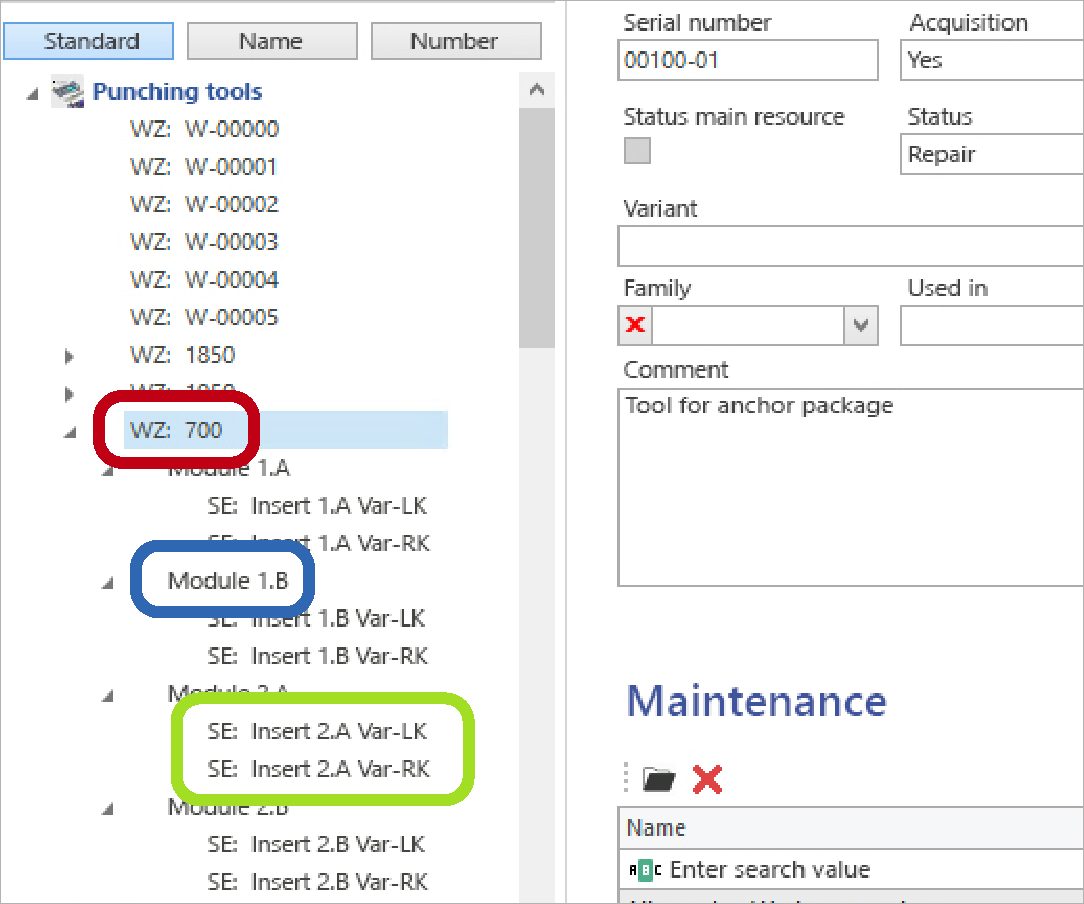

Digital maintenance of tools in all their complexity

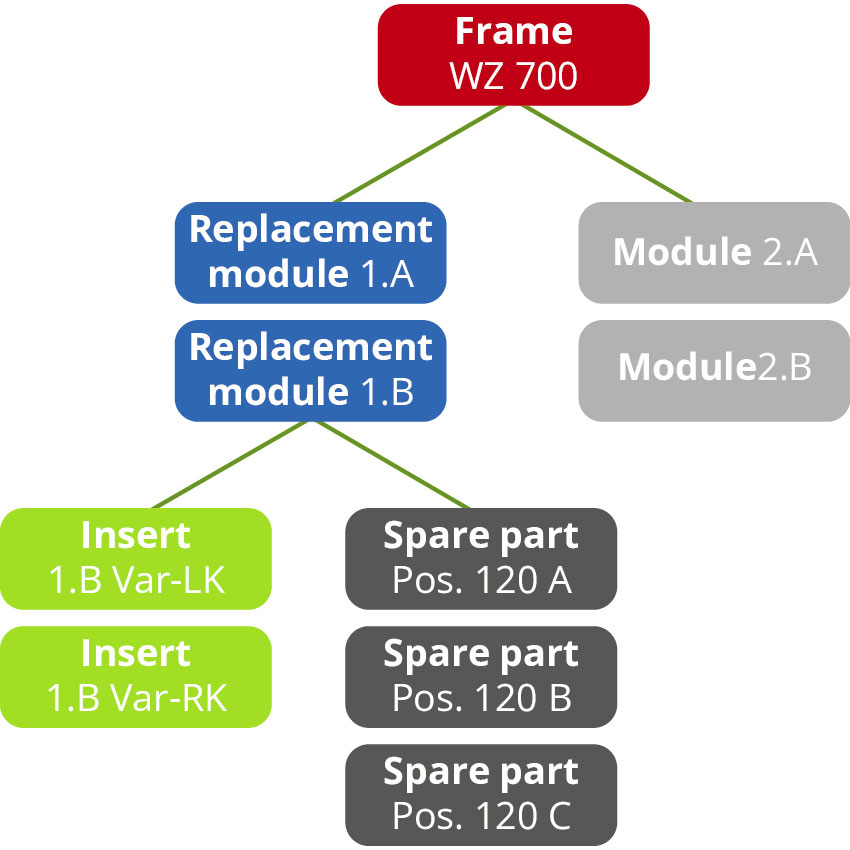

The master data of the tool forms the basis for complete documentation of the entire life cycle of a tool in the digital life cycle card. Complex tools are structured in a tree structure with categories and category groups that can be freely defined. Simple tools do not require any detailing.

Service life and maintenance can be assigned in detail to the frame, modules, assemblies, and inserts. Information about the manufacturer, date of purchase, or even the complete machine documentation can be easily stored.

Digital maintenance for transparency and real-time control

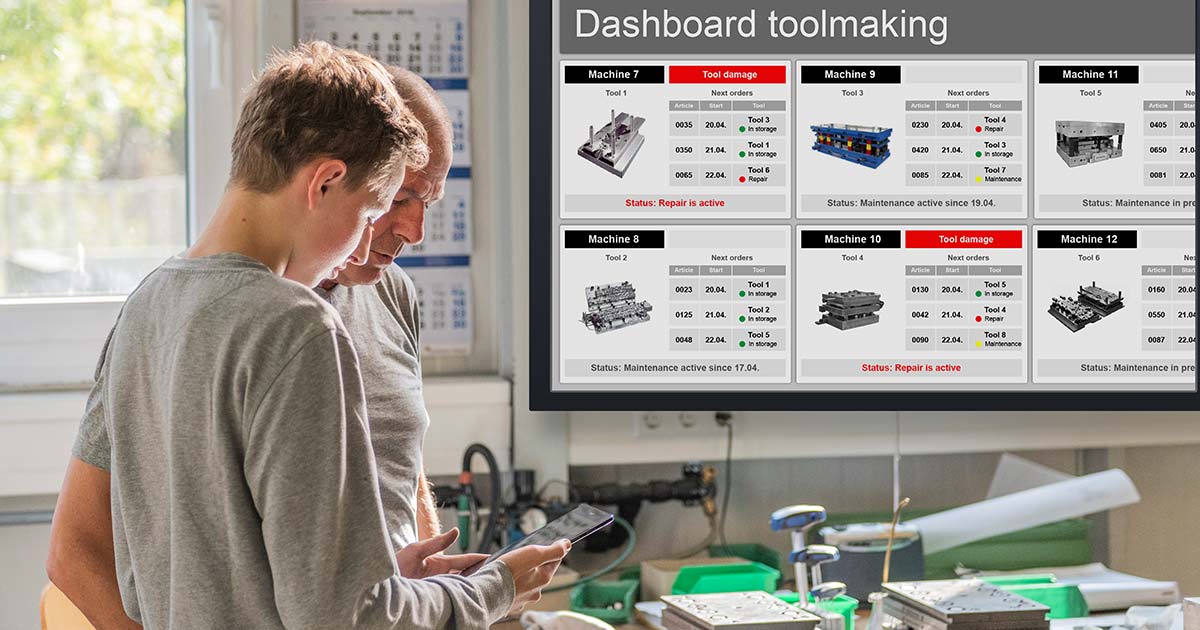

The classic scenario: The machine is down due to tool damage. And it stays down. And stays down… The tool shop is initially unaware of the downtime. The digital maintenance process provides the solution.

Malfunctions and downtime are displayed directly on the dashboard in the tool shop. This allows maintenance to respond immediately, rather than waiting for someone from production to report the problem. All work performed, spare parts used, and comments are systematically documented. This means that everyone involved knows at all times what condition the machines and tools are in, how often they have been used, and when the next maintenance is due.

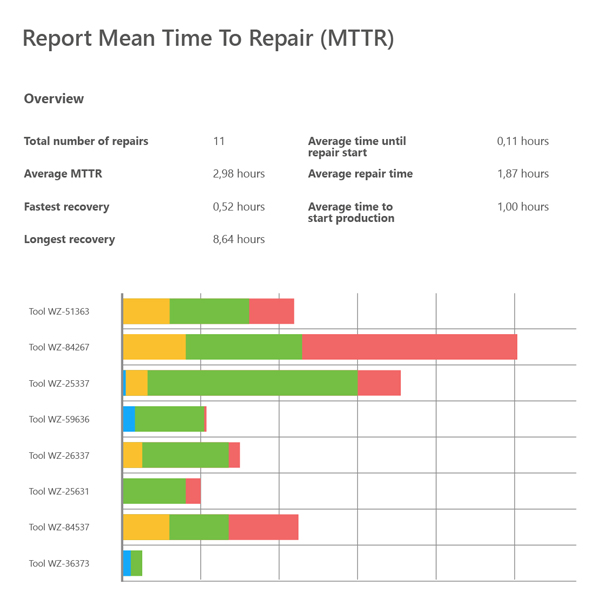

Turning digital tool data into knowledge

Which tool inserts are responsible for production downtime? Which spare part needs to be replaced most frequently? How many benders should be kept in stock for production? These and other questions are answered using the recorded and documented data. Tool design can draw on a wealth of data to optimize the tool. This makes a significant contribution to increasing productivity.

Analyses of the correlation between orders, rejects, and maintenance performed are an important basis for decision-making.

All modules: